GM-0137 Prototype aluminum casting

Key words:

Classification:

Product Description

Product name: Prototype aluminum casting

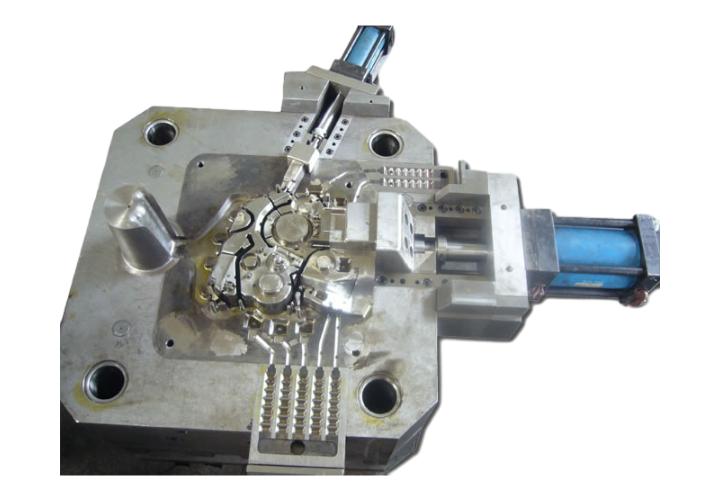

Molding process: heat treatment / machining / wire cutting / discharge / nano-coating, etc

Mold material: mold kernel 8418, mold embryo 45 # steel, oil cylinder, etc

Molding cycle: 35 days

Other remarks: Support for graph customization

Prototype aluminum casting is an industrial product with great significance and wide application.

First of all, aluminum, as the main material, has a series of outstanding advantages. It is relatively light, which makes the final casting have an advantage in weight, easy to transport and install, and also provides an ideal choice for some application scenarios with strict weight requirements. Moreover, aluminum has good corrosion resistance and can remain stable under various environmental conditions, reducing the cost of maintenance and replacement.

In terms of manufacturing process, prototype aluminum casting shows a high degree of precision and flexibility. Through advanced die-casting technology, liquid aluminum can be accurately injected into the mold to obtain complex shapes that are highly consistent with the design. This process can achieve extremely high dimensional accuracy and surface quality, making prototype aluminum casting not only exquisite and beautiful in appearance, but also meet various strict requirements in function.

Inquiry

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695