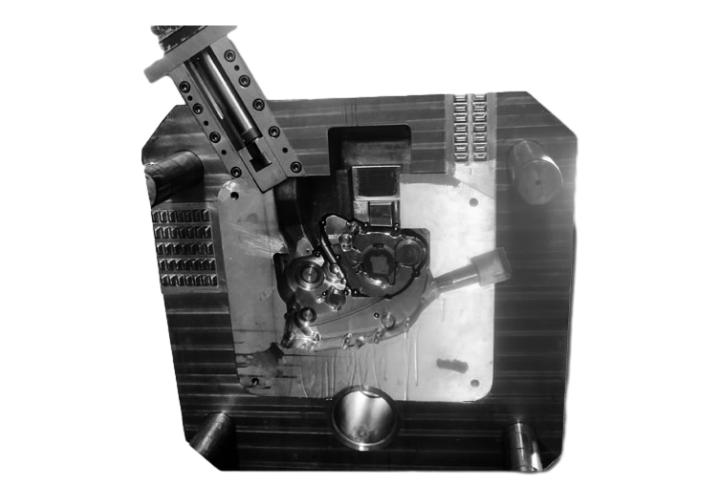

GM-0138 Prototype aluminum casting

Key words:

Classification:

Product Description

Product name: Prototype aluminum casting

Molding process: heat treatment / machining / wire cutting / discharge / nano-coating, etc

Mold material: mold kernel 8418, mold embryo 45 # steel, oil cylinder, etc

Molding cycle: 35 days

Other remarks: Support for graph customization

The advantages of prototype aluminum casting are also reflected in its customizability. Whether it is a special shape design, unique functional requirements, or specific performance indicators, it can be achieved by adjusting the manufacturing process and mold design. This enables it to meet the diverse needs of different customers and different industries.

In addition, prototype aluminum casting also plays a key role in the process of research and development and innovation. In the early stages of new product development, by quickly manufacturing prototype aluminum casting, various tests and verifications can be carried out, so as to timely discover problems and improve the design, greatly shorten the product development cycle, and reduce R&D costs.

From a quality perspective, strict production management and quality control ensure that every prototype aluminum casting has excellent quality. Advanced testing equipment and technical means will conduct a comprehensive and detailed inspection of the product, without missing any subtle defects. This not only ensures the stability of the product's performance, but also provides customers with reliable protection.

In terms of environmental protection, aluminum is a recyclable material. After its life cycle, prototype aluminum casting can be recycled and reused to reduce the impact on the environment. This is in line with today's society's pursuit of sustainable development and shows its green and environmentally friendly characteristics.

Inquiry

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695