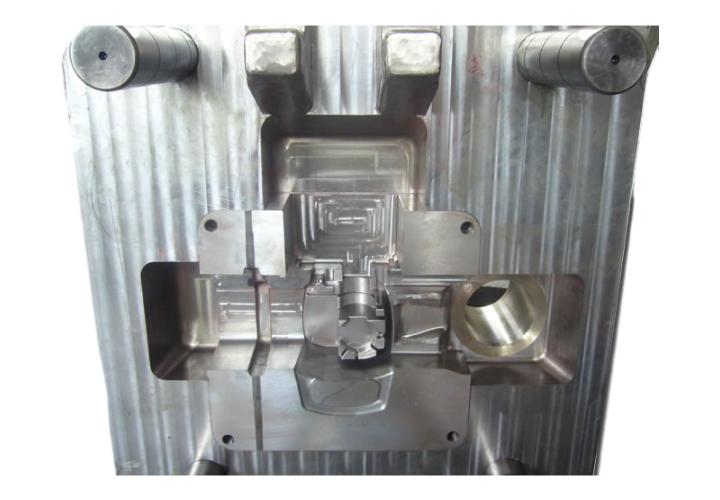

GM-0142 Zinc alloy mold

Key words:

Classification:

Product Description

Product name: Zinc alloy mold

Molding process: heat treatment / machining / wire cutting / discharge / nano-coating, etc

Mold material: mold kernel 8418, mold embryo 45 # steel, oil cylinder, etc

Molding cycle: 35 days

Other remarks: Support for graph customization

Zinc alloy mold has many remarkable characteristics. First, it has good casting performance and can form various complex shapes more accurately to meet the needs of different product designs. This allows it to produce products with fine structures and high precision. Secondly, zinc alloy has high strength and hardness, which can maintain good stability and durability during the production process, ensuring that the mold can be used repeatedly without being easily damaged.

Zinc alloy mold is also indispensable for the plastic products industry. It can be used to make molds for various plastic products and produce plastic products with diverse shapes and excellent quality. In addition, in the fields of toy manufacturing, household goods, etc., Zinc alloy mold also plays an important role, providing reliable support for the production of various products.

Inquiry

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695