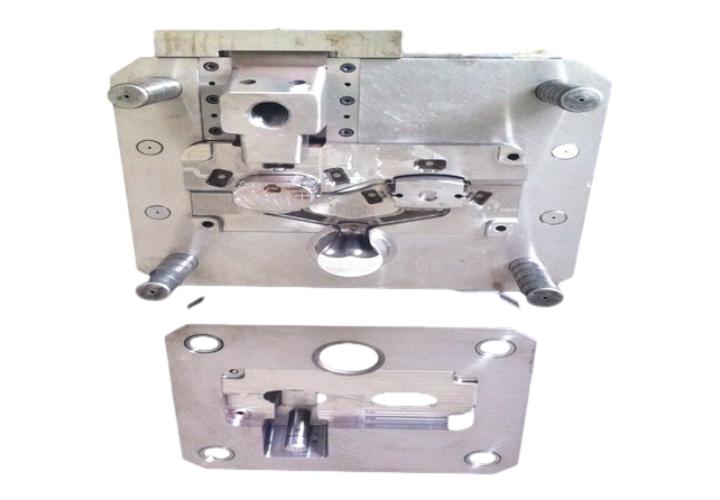

GM-0152 Aluminum die casting mold

Key words:

Classification:

Product Description

Product name: Aluminum die casting mold

Molding process: heat treatment / machining / wire cutting / discharge / nano-coating, etc

Mold material: mold kernel 8418, mold embryo CH2030, oil cylinder, etc

Molding cycle: 45 days

Other remarks: Support for graph customization

Product Description:

During the manufacturing process, aluminum die casting mold needs to undergo rigorous processing and debugging. Including a series of processes such as mold design, CNC machining, EDM, polishing, etc., each link requires a high degree of professional skills and experience. At the same time, in order to ensure the quality and performance of the mold, strict testing and verification are also required, such as size detection, hardness testing, flaw detection, etc.

The service life of aluminum die casting mold is also an important consideration. Through reasonable design, material selection, processing technology and maintenance, the service life of the mold can be effectively extended and the production cost can be reduced. During use, attention should be paid to the cooling, lubrication and cleaning of the mold to avoid damage to the mold due to improper operation.

From the material point of view, the materials used to manufacture aluminum die casting mold usually have high strength, high hardness, high wear resistance and good heat resistance. These characteristics enable the mold to work stably for a long time in a high temperature and high pressure die casting environment, and withstand frequent die casting cycles without being easily damaged. Common mold materials include high-quality tool steel, etc., which are properly heat treated and processed to improve their performance.

Inquiry

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695