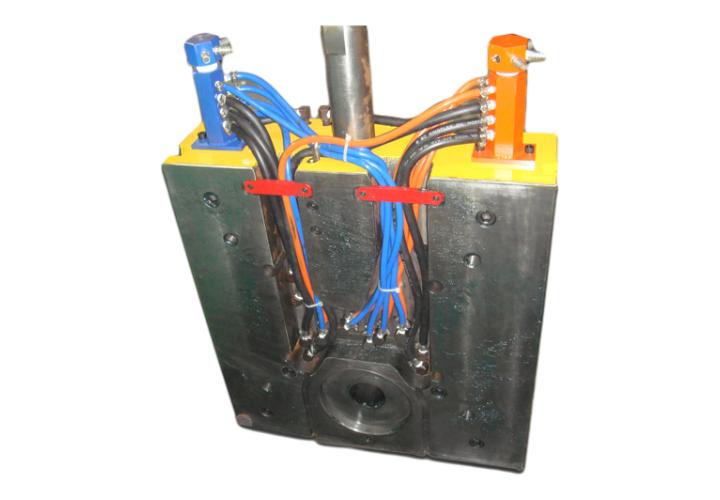

GM-0154 Steel mold for aluminum casting

Classification:

Product Description

Product name: Steel mold for aluminum casting

Molding process: heat treatment / machining / wire cutting / discharge / nano-coating, etc

Mold material: mold kernel 8418, mold embryo CH2030, oil cylinder, etc

Molding cycle: 45 days

Other remarks: Support for graph customization

In the automotive industry, engine parts and body structural parts produced by steel mold for aluminum casting have made important contributions to the lightweight and performance improvement of automobiles. Some key parts in the aerospace field also benefit from this mold, achieving a perfect combination of high strength and lightweight. In electronic equipment, such as mobile phone casings and computer accessories, steel mold for aluminum casting also ensures the exquisite appearance and reliable performance of the product.

However, the manufacture of steel mold for aluminum casting is not easy. It requires strict processing technology and exquisite technical means. Starting from the selection of mold materials, high-quality steel needs to be carefully selected to ensure that its performance meets the requirements. The subsequent CNC machining, EDM machining, heat treatment and other processes all require highly professional technicians to operate and control. Negligence in any link may cause quality problems in the mold.

In order to ensure the good performance and long service life of steel mold for aluminum casting, daily maintenance and care are also very important. After use, the aluminum slag and other impurities on the surface of the mold should be cleaned in time, the mold should be inspected and repaired regularly, and possible wear, cracks and other problems should be discovered and dealt with in time.

Inquiry

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695