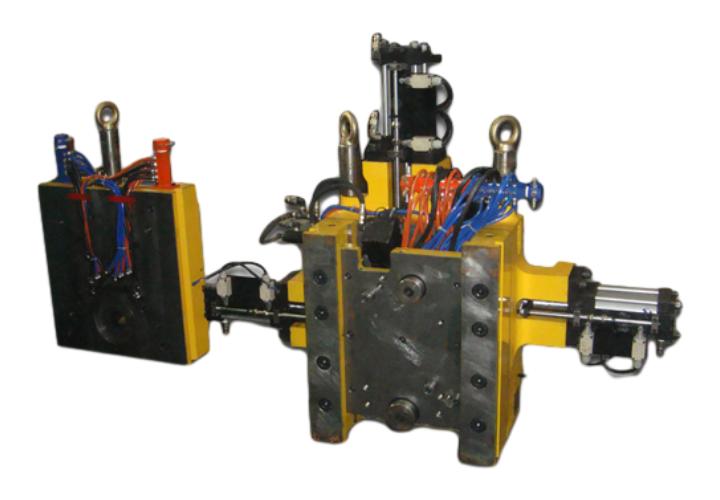

GM-0156 Aluminum alloy mold

Key words:

Classification:

Product Description

Product name: aluminum alloy mold

Molding process: heat treatment / machining / wire cutting / discharge / nano-coating, etc

Mold material: mold kernel 8418, mold embryo CH2030, oil cylinder, etc

Molding cycle: 45 days

Other remarks: Support for graph customization

Aluminum alloy mold is a type of mold that plays an important role in modern industry.

Aluminum alloy mold has many outstanding advantages. First, it is relatively light, which makes it easier to carry and operate, especially in some occasions where the mold needs to be moved frequently or there are strict weight restrictions. Secondly, aluminum alloy has good thermal conductivity and can quickly transfer heat, which is very beneficial for some production processes that require rapid cooling or heating. Moreover, aluminum alloy has a certain strength and hardness, which can withstand the pressure and wear during the production process and ensure the service life of the mold.

Aluminum alloy mold has been widely used in many industries. In the field of automotive parts manufacturing, it is often used to produce some small parts molds with more complex structures, such as aluminum alloy wheel molds. Its lightweight characteristics help to reduce the weight of the whole vehicle and improve the performance and fuel efficiency of the vehicle. In the electronics industry, aluminum alloy mold can be used to produce various precision electronic parts molds, and its good processing performance and precision ensure the high quality of electronic products.

The aerospace field is also where aluminum alloy mold can show its prowess. For some weight-sensitive aviation parts, aluminum alloy mold can minimize weight while meeting strength requirements. At the same time, in some high-end manufacturing industries, such as medical device manufacturing, aluminum alloy mold can also play an important role, providing guarantee for the production of high-precision and high-quality medical devices.

Another advantage of aluminum alloy mold is its good machinability. It can be made into molds of various shapes and sizes through a variety of processing techniques, such as casting, extrusion, CNC machining, etc., to meet the needs of different products. Moreover, the surface treatment of aluminum alloy mold is relatively easy, and good surface quality and corrosion resistance can be obtained through various methods.

However, aluminum alloy mold is not perfect. Compared with some other high-strength mold materials, its strength and hardness may be slightly inferior. In some high-load and high-pressure production environments, it may need to be used and maintained more carefully. In addition, aluminum alloys may suffer from corrosion and other problems in certain special environments, and appropriate protective measures need to be taken.

In order to give full play to the advantages of aluminum alloy mold, the following points should be noted during use. First, it is necessary to reasonably select the grade and performance of aluminum alloy according to specific production needs. Second, it is necessary to strengthen the design and manufacturing process of the mold to ensure that the mold has a reasonable structure and high precision. Third, we must do a good job of daily maintenance and care, regularly check the status of the mold, and discover and deal with problems in a timely manner.

Inquiry

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695