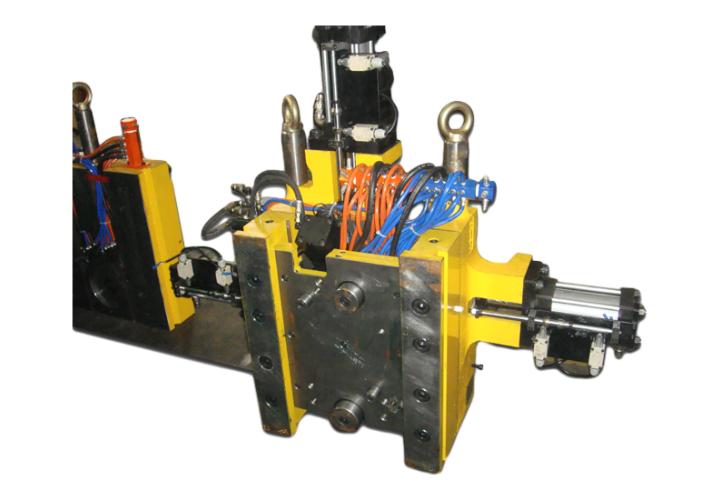

GM-0157 Prototype aluminum casting

Classification:

Product Description

Product name: aluminum alloy mold

Molding process: heat treatment / machining / wire cutting / discharge / nano-coating, etc

Mold material: mold kernel 8418, mold embryo CH2030, oil cylinder, etc

Molding cycle: 45 days

Other remarks: Support for graph customization

Prototype aluminum casting is mainly used in the product development and testing stage, which can quickly transform design concepts into entities. This casting is made of aluminum alloy material and has a series of excellent properties. Aluminum alloy has a light weight, which is very beneficial for situations where the overall weight of the product needs to be considered, such as in aerospace, automotive and other fields, which can reduce the weight of equipment, improve performance and fuel efficiency.

In terms of strength, Prototype aluminum casting also performs well, and can withstand certain pressures and loads to ensure the stability and reliability of the product during use. Its good thermal conductivity also makes it used in products with high heat dissipation requirements.

Its manufacturing process usually uses advanced casting technology, which can accurately replicate design details and highly restore the designer's creativity. In this way, potential problems in the design can be discovered in the early stage, and adjustments and optimizations can be made in time, thereby saving time and cost in subsequent development.

Prototype aluminum casting also has good machinability, and can be further processed and processed according to specific needs, such as drilling, cutting, grinding, etc., to meet the special requirements of different products.

Inquiry

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695