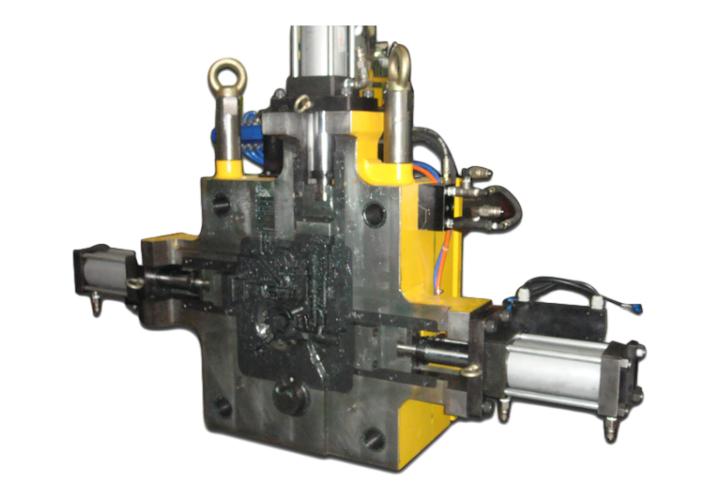

GM-0158 Steel mold for aluminum casting

Key words:

Classification:

Product Description

Product name: aluminum alloy mold

Molding process: heat treatment / machining / wire cutting / discharge / nano-coating, etc

Mold material: mold kernel 8418, mold embryo CH2030, oil cylinder, etc

Molding cycle: 45 days

Other remarks: Support for graph customization

Steel mold for aluminum casting is an indispensable key tool in the production process of aluminum castings. It plays a vital role in ensuring the high quality, high precision and high efficiency of aluminum castings.

This steel mold is usually made of high-quality steel with excellent strength and wear resistance. The selection of steel is carefully considered to adapt to the high temperature, high pressure and frequent use in the casting process. Its sturdy structure can withstand repeated filling and solidification processes to ensure that the mold maintains stable performance in long-term use.

The design of steel mold for aluminum casting is very sophisticated. Professional engineers will carry out detailed design and planning according to the specific shape and requirements of aluminum castings. The cavity design of the mold should accurately match the shape of the aluminum casting to ensure that the product with precise size and smooth surface can be produced. At the same time, the mold will also design a reasonable gating system, exhaust system, etc. to optimize the casting process and reduce the occurrence of defects.

Inquiry

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695