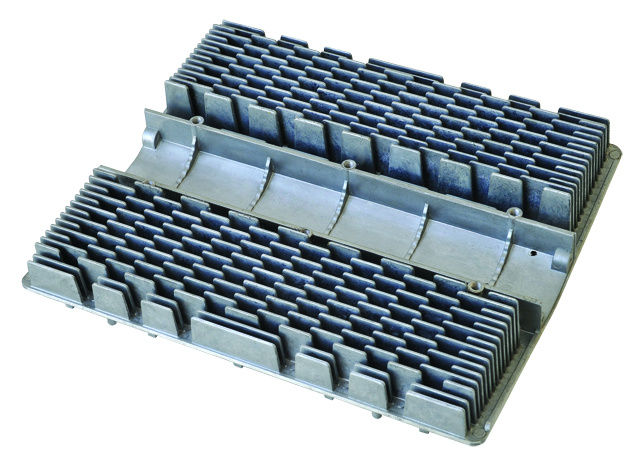

GM-D1026 china custom aluminum casting

Key words:

Classification:

Product Description

Product name: spotlight radiator custom aluminum casting

Molding process: cold-type die-casting

Product material: ADC 12-aluminum alloy

Surface treatment: electrophoresis / powder spraying

Opening mold cycle: 45 days

Production cycle: 45 days

Other remarks: Support for graph customization

Custom aluminum casting is an advanced and highly practical manufacturing process that plays an important role in many fields.

Aluminum, as a widely used metal material, has many excellent properties such as light weight, high strength, and corrosion resistance. Custom aluminum casting further amplifies and optimizes these advantages of aluminum.

In the custom aluminum casting process, liquid aluminum can be accurately injected into the mold through a carefully designed mold, and after cooling, various parts or products with complex shapes and precise dimensions can be formed. This allows us to create unique aluminum items based on the specific needs of different customers.

Its advantages are very significant. First of all, it can realize highly complex geometric shape design, whether it is fine texture or unique structure, it can be easily formed. This provides product designers with great creative space to create a variety of new and unique products. Secondly, custom aluminum casting can achieve high-efficiency mass production, significantly reducing production costs while ensuring quality. Furthermore, aluminum die-casting products have good mechanical properties and can meet the requirements of a variety of harsh use environments.

Inquiry

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695