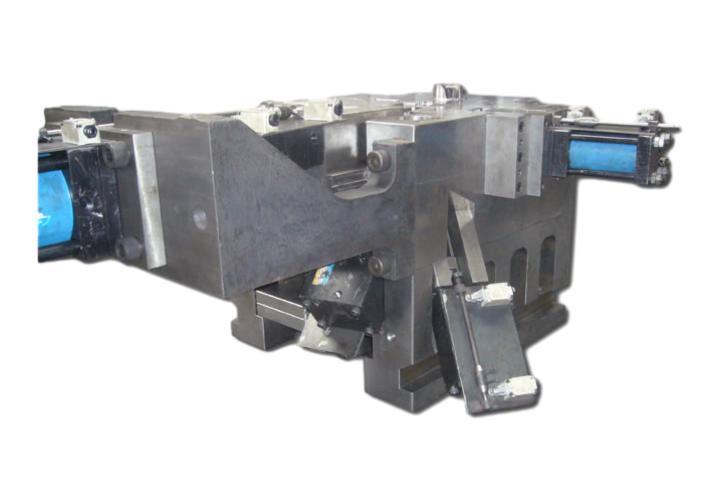

GM-0144 Zinc alloy mold

Key words:

Classification:

Product Description

Product name: Zinc alloy mold

Molding process: heat treatment / machining / wire cutting / discharge / nano-coating, etc

Mold material: mold kernel 8418, mold embryo 45 # steel, oil cylinder, etc

Molding cycle: 35 days

Other remarks: Support for graph customization

In order to ensure the good performance of Zinc alloy mold, the following points should be noted during production and use. First, it is necessary to select high-quality zinc alloy materials to ensure that their composition and performance meet the requirements. Second, it is necessary to carry out fine mold design and manufacturing to give full play to the advantages of zinc alloy. Third, it is necessary to do a good job in daily maintenance and maintenance, regularly check the status of the mold, and promptly discover and deal with problems.

In short, Zinc alloy mold has become an indispensable part of modern industrial production with its unique performance and wide applicability. It provides high-quality and efficient mold solutions for various industries, helping enterprises to improve product quality and production efficiency. With the continuous advancement and innovation of technology, it is believed that Zinc alloy mold will continue to play an important role in the future and continue to expand its application areas.

Inquiry

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695