GM-0145 Zinc die casting parts

Key words:

Classification:

Product Description

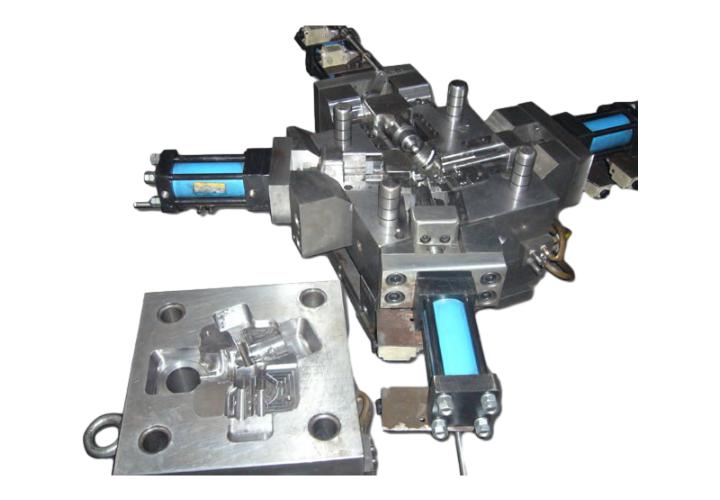

Product name: Zinc die casting parts

Molding process: heat treatment / machining / wire cutting / discharge / nano-coating, etc

Mold material: mold kernel 8418, mold embryo 45 # steel, oil cylinder, etc

Molding cycle: 35 days

Other remarks: Support for graph customization

The application range of zinc die casting parts is extremely wide. In the automotive field, they are used to manufacture engine parts, gearbox housings, automotive interior parts, etc. These parts not only support the performance of the car, but also play an important role in reducing the weight of the car body and improving fuel efficiency. In the electronics industry, zinc die casting parts are often used to manufacture electronic product housings, radiators, etc., providing good protection and heat dissipation functions for electronic equipment. In addition, zinc die casting parts can be seen in many fields such as machinery manufacturing, household goods, and medical equipment.

Its advantages also include high production efficiency. Once the mold is manufactured, a large number of zinc die casting parts of the same specifications can be produced quickly to meet the needs of large-scale production. In addition, by continuously optimizing the mold design and die-casting process, production efficiency and product quality can be further improved.

Zinc die casting parts also have great flexibility in design. Various complex shapes and structures can be designed according to different needs to meet the requirements of product diversification. Whether it is a simple geometric shape or a complex curved surface structure, it can be easily achieved through the zinc die casting process.

Inquiry

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695