GM-0146 Zinc die casting parts

Key words:

Classification:

Product Description

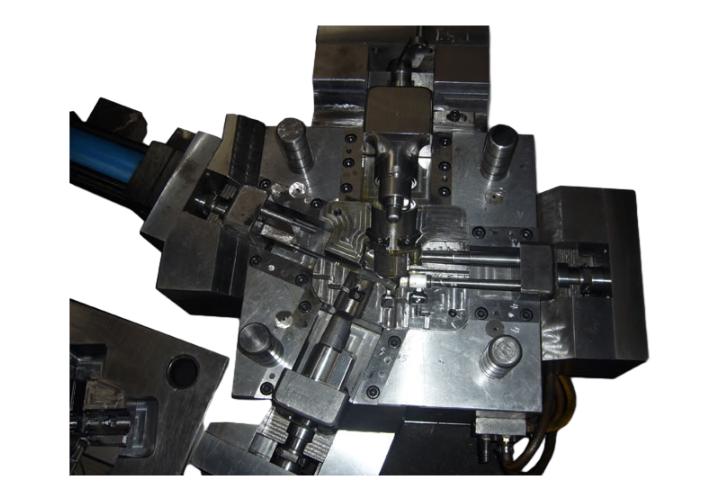

Product name: Zinc die casting parts

Molding process: heat treatment / machining / wire cutting / discharge / nano-coating, etc

Mold material: mold kernel 8418, mold embryo 45 # steel, oil cylinder, etc

Molding cycle: 35 days

Other remarks: Support for graph customization

Zinc die casting parts are an extremely important component in modern industry.

Zinc, as the main material, has many characteristics that make it an ideal choice for die casting. It has good fluidity and can evenly fill complex mold cavities during the die casting process, thereby producing parts with exquisite shapes and rich details. Moreover, zinc has a relatively low melting point, which is conducive to reducing energy consumption and costs in the die casting process.

Zinc die casting parts excel in performance. They have high strength and hardness, can withstand certain pressures and loads, and ensure stable and reliable operation in various application scenarios. At the same time, zinc has good corrosion resistance and can maintain its performance and appearance under different environmental conditions.

From the perspective of manufacturing process, the zinc die casting process is highly accurate and repeatable. Through advanced die casting equipment and technology, the size, shape and surface quality of the parts can be precisely controlled. This precision enables zinc die casting parts to work perfectly with other components to ensure the normal operation of the entire system.

Inquiry

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695