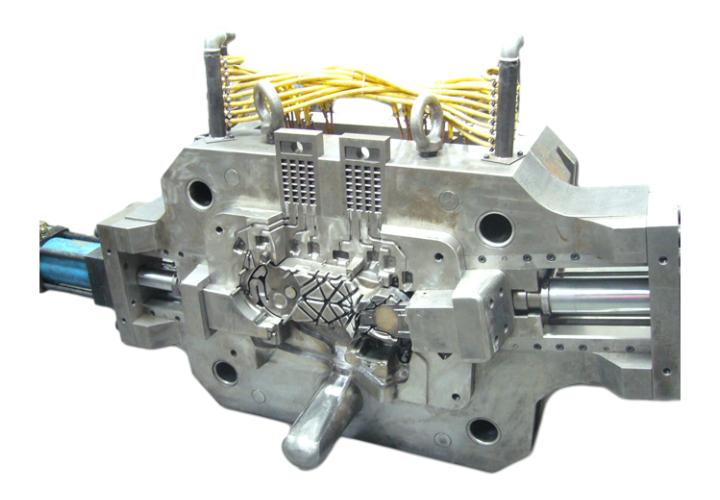

GM-0148 Zinc alloy die casting

Classification:

Product Description

Product name: zinc alloy die casting

Molding process: heat treatment / machining / wire cutting / discharge / nano-coating, etc

Mold material: mold kernel 8418, mold embryo 45 # steel, oil cylinder, etc

Molding cycle: 35 days

Other remarks: Support for graph customization

Zinc alloy die casting is an advanced and widely used manufacturing process. The zinc alloy die casting products produced have many significant features and advantages.

Zinc alloy die casting products first perform well in appearance. They are able to achieve complex and fine shapes and structures, with high dimensional accuracy and surface finish, and can meet various application scenarios with high appearance requirements.

From the perspective of material properties, zinc alloy has good fluidity and filling properties, which allows the die-casting process to proceed smoothly and products with thin walls and complex structures can be manufactured. At the same time, zinc alloy also has good mechanical properties, such as certain strength and hardness, and can adapt to different use environments and working conditions.

Inquiry

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695