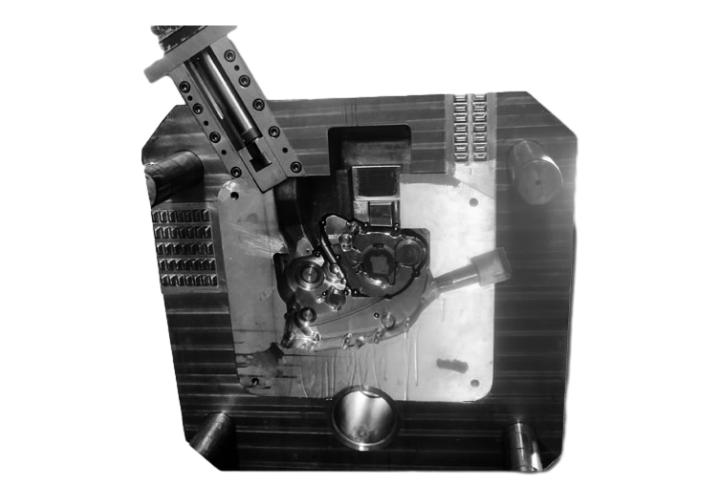

GM-0149 Zinc alloy die casting

Classification:

Product Description

Product name: Zinc alloy die casting

Molding process: heat treatment / machining / wire cutting / discharge / nano-coating, etc

Mold material: mold kernel 8418, mold embryo 45 # steel, oil cylinder, etc

Molding cycle: 35 days

Other remarks: Support for graph customization

In terms of application, zinc alloy die casting covers multiple fields. In the automotive industry, many parts such as car handles and decorative parts are often made of zinc alloy die casting, which not only provides reliable performance, but also adds beauty to the car. In the electronics industry, various housings, connectors, etc. also benefit from the advantages of zinc alloy die casting, with good protection and durability. In the field of furniture and hardware, zinc alloy die-casting handles, locks and other products are also widely available, bringing convenience to daily life.

Zinc alloy die casting also has good machinability. Its performance and appearance can be further improved through subsequent processing, such as drilling, tapping, polishing, etc. Moreover, zinc alloy can be subjected to a variety of surface treatments, such as electroplating, spraying, etc., to obtain different colors and decorative effects to meet diverse market needs.

In the production process, zinc alloy die casting technology is highly efficient. It can achieve large-scale production, quickly manufacture a large number of products, effectively reduce costs and improve production efficiency. At the same time, through precise mold design and process control, the consistency and stability of product quality can be ensured.

Inquiry

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695