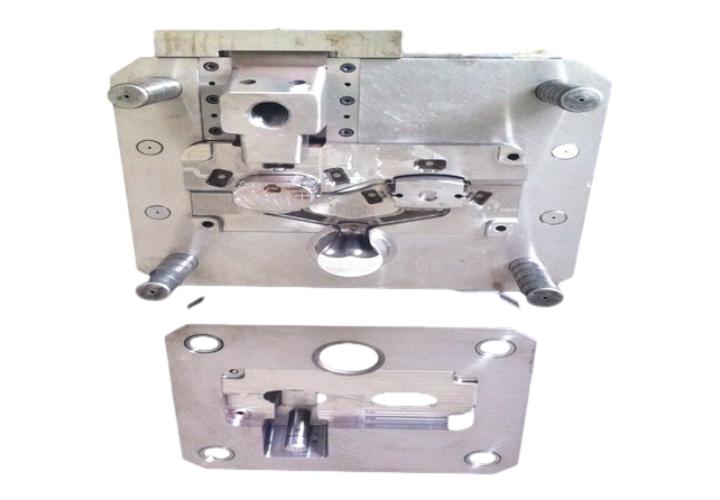

GM-0198 Aluminum alloy mold

Key words:

Classification:

Product Description

Product name: aluminum alloy mold

Molding process: heat treatment / machining / wire cutting / discharge / nano-coating, etc

Mold material: mold kernel 8418, mold embryo CH2030, etc

Molding cycle: 45 days

Other remarks: Support for graph customization

Aluminum alloy mold is a type of mold that plays an important role in modern industry.

Aluminum alloy mold has many outstanding advantages. First, it is relatively light, which makes it easier to carry and operate, especially in some occasions where the mold needs to be moved frequently or there are strict weight restrictions. Secondly, aluminum alloy has good thermal conductivity and can quickly transfer heat, which is very beneficial for some production processes that require rapid cooling or heating. Furthermore, aluminum alloy has a certain strength and hardness, which can withstand the pressure and wear in the production process and ensure the service life of the mold.

In order to give full play to the advantages of aluminum alloy mold, the following points should be noted during use. First, it is necessary to reasonably select the grade and performance of aluminum alloy according to specific production needs. Second, it is necessary to strengthen the design and manufacturing process of the mold to ensure that the mold has a reasonable structure and high precision. Third, it is necessary to do a good job in daily maintenance and maintenance, regularly check the status of the mold, and promptly discover and deal with problems.

Inquiry

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695