GM-0199 custom aluminum molds suppliers

Key words:

Classification:

Product Description

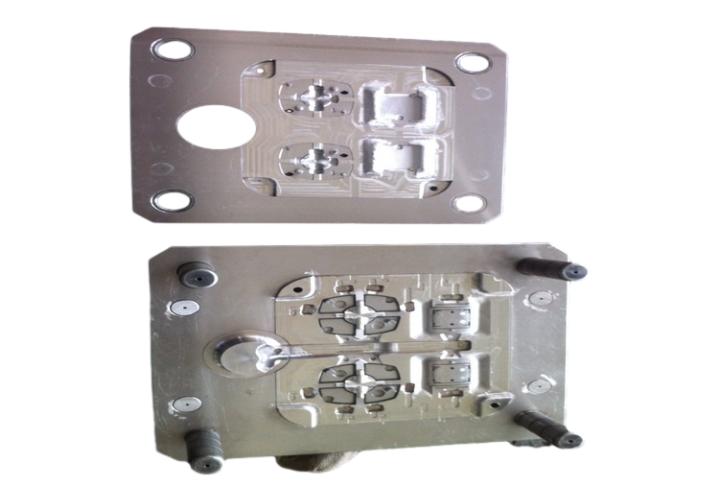

Product name: custom aluminum molds

Molding process: heat treatment / machining / wire cutting / discharge / nano-coating, etc

Mold material: mold kernel 8418, mold embryo CH2030, etc

Molding cycle: 45 days

Other remarks: Support for graph customization

Our custom aluminum molds first show excellence in design. We have an experienced and creative design team who work closely with customers to deeply understand their product needs, production processes and special requirements. By using advanced computer-aided design software, we can accurately draw the details of each mold to ensure that it perfectly matches the customer's expectations.

During the manufacturing process, we adhere to the attitude of striving for excellence. We use the most advanced processing equipment and processes to carefully carve aluminum. Whether it is complex geometric shapes or high-precision dimensional requirements, they can be accurately achieved. Strict quality control runs through the entire process, and every production link is strictly tested and checked to ensure that the quality of the mold reaches the top level.

This custom aluminum mold is widely used in many fields. In the automotive manufacturing industry, it can be used to produce various parts to support the lightweight and high performance of automobiles. In the electronics industry, it can help manufacture precision electronic device housings to ensure their quality and reliability. In the plastic products industry, it provides a solid guarantee for the efficient molding of plastic products.

In addition, our custom aluminum molds are also highly repeatable and stable. Once the design and manufacturing are completed, it can continuously and stably produce high-quality products for a long time, greatly improving production efficiency and product consistency. Moreover, we provide a full range of after-sales services, respond promptly to problems encountered by customers during use, and ensure that the mold is always in the best condition.

Inquiry

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695