Knowledge

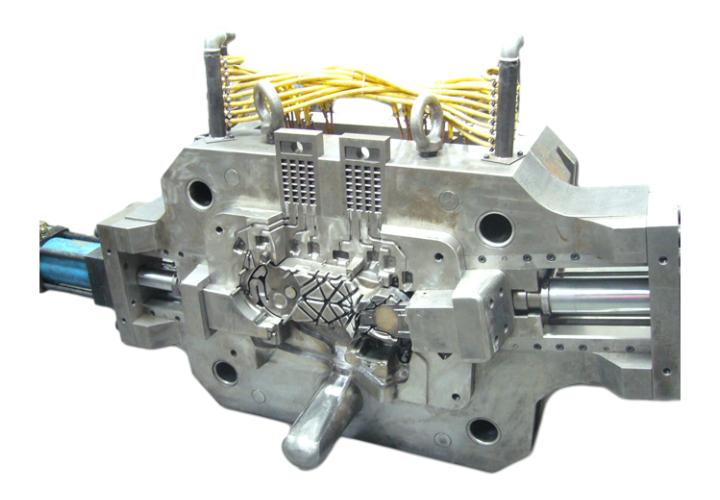

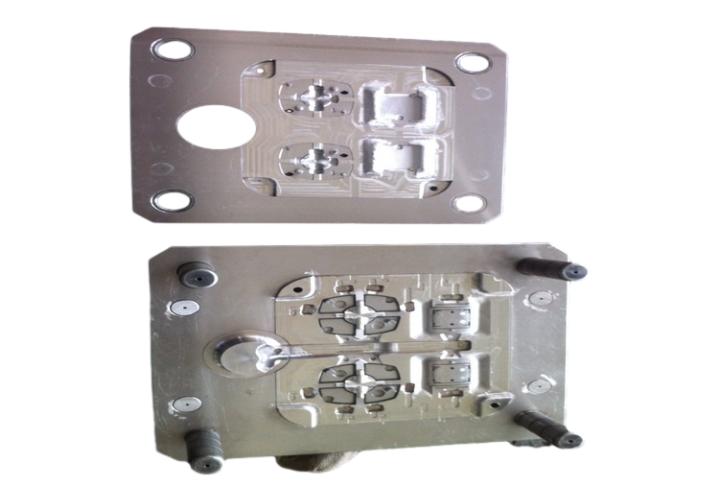

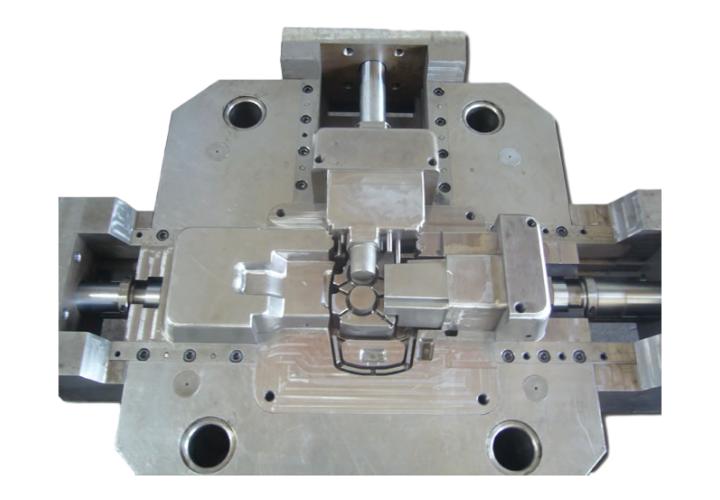

Understanding Die Casting Molds: Key Insights for Professionals in the Manufacturing Industry

Elevating Quality Standards: The Role of Aluminum Casting in Mechanical Processing

Efficiency Redefined: Advancements in Zinc Die Casting for Molding

Understanding Die Casting Machines: An Essential Guide for Metalworking Professionals

Unleashing the Potential of Aluminum Die Casting in Modern Manufacturing

Understanding Aluminum Alloy Molds: A Key Component in Precision Manufacturing

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695