18

2024

-

10

Die casting alloy

Author:

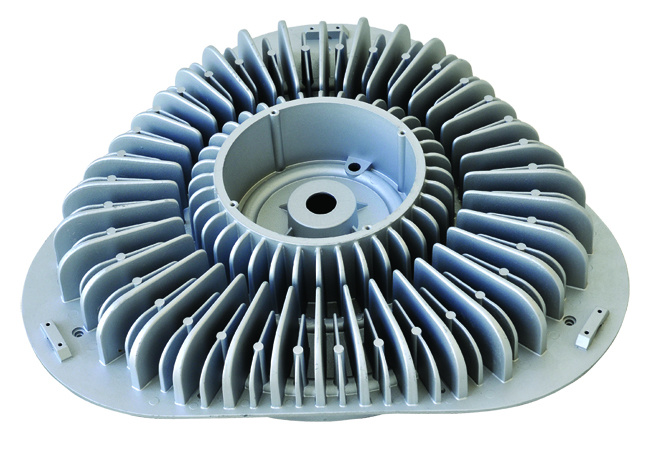

Product name: lamp radiator die casting alloy

Molding process: cold-type die-casting

Product material: ADC 12-aluminum alloy

Surface treatment: electrophoresis / powder spraying

Opening mold cycle: 45 days

Production cycle: 45 days

Other remarks: Support for graph customization

Die casting alloy is a material that plays a key role in the die casting process.

Die casting alloy has a series of outstanding characteristics. They usually have good fluidity and can quickly and evenly fill the mold cavity during the die casting process, thereby ensuring the integrity and accuracy of the molding. At the same time, they have high strength and hardness, so that the die casting products can withstand certain pressure and load. In addition, die casting alloy also has good corrosion resistance and can maintain stable performance under different environmental conditions.

Among the many die casting alloys, aluminum alloy is a widely used one. Aluminum alloy die casting alloy has a lighter density, which is a great advantage for products that pursue lightweight. It also has good thermal conductivity and electrical conductivity, and is suitable for some occasions that require thermal conduction and electrical properties. Magnesium alloy is also one of the common die casting alloys. Its density is smaller than that of aluminum alloy and has a better weight reduction effect, but the cost is relatively higher. Zinc alloy is favored for its good casting performance and low cost, and is often used in the manufacture of some daily necessities and small parts that do not require so much strength.

Die casting alloy

Previous Page

Next Page

Previous Page

Next Page

09

2025-12

Innovative Designs Made Possible: The Influence of Die Casting Machines

06

2025-12

Understanding Aluminum Die Casting: A Comprehensive Guide for Manufacturers

03

2025-12

The Future of Machining: Innovations in Aluminum Alloy Mold Advancements

30

2025-11

The Advantages and Applications of Zinc Alloy Molds in Manufacturing

27

2025-11

Exploring the Versatility of Zinc Alloy in Modern Applications

24

2025-11

Exploring the Versatility and Applications of Aluminum Alloys

21

2025-11

Revolutionizing the World of Molding: The Advantages of Aluminum Casting

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695