09

2025

-

08

How to Improve the Reusable Life of Aluminum Die Casting Molds

Author:

Aluminum die casting molds are critical equipment for efficient mass production. Their quality and service life directly impact a company's production costs and product consistency. Due to the harsh operating conditions of the die casting process, such as high temperature, high pressure, and strong erosion, molds are often prone to problems such as thermal fatigue cracking, sticking, and wear. Extending the reusable life of molds has become a key concern in the die casting industry.

First, selecting high-quality mold steel is fundamental. Commonly used steels for aluminum die casting molds, such as H13 and 8407, should possess excellent thermal strength, thermal fatigue resistance, and corrosion resistance. Choosing the right material at the initial mold design stage, based on product complexity and production batch size, lays a solid foundation for mold life.

Second, optimizing mold structural design is also crucial. A reasonable cooling system layout can effectively control mold temperature and reduce thermal stress accumulation. Furthermore, improving the exhaust system design can prevent gas stagnation and localized high-temperature erosion, improve overall mold stress balance, and reduce wear at the source.

Third, controlling production parameters and mold temperature is crucial for ensuring mold life. During the die-casting process, injection speed, pressure, and alloy melting temperature should be appropriately set to prevent fatigue cracks in the mold caused by excessive temperature fluctuations or frequent thermal expansion and contraction. A mold temperature control system can maintain the mold operating within the ideal temperature range, effectively delaying thermal fatigue aging.

In addition, strengthening mold surface treatment can significantly extend mold life. Processes such as nitriding, carburizing, and PVD coating can enhance mold surface hardness and anti-adhesion properties, thereby improving wear and corrosion resistance.

Finally, daily maintenance and repair management should be emphasized. After each production run, the mold cavity should be cleaned of debris, the mold should be inspected for cracks or wear, and key areas should be properly lubricated and cooled. A usage log should be maintained to plan maintenance and replacement procedures.

Increasing the reusable life of aluminum die-casting molds requires coordinated optimization of multiple aspects, including material selection, structural design, production control, surface treatment, and post-maintenance. Only by establishing a comprehensive management mechanism can efficient and stable mold operation and maximize economic benefits.

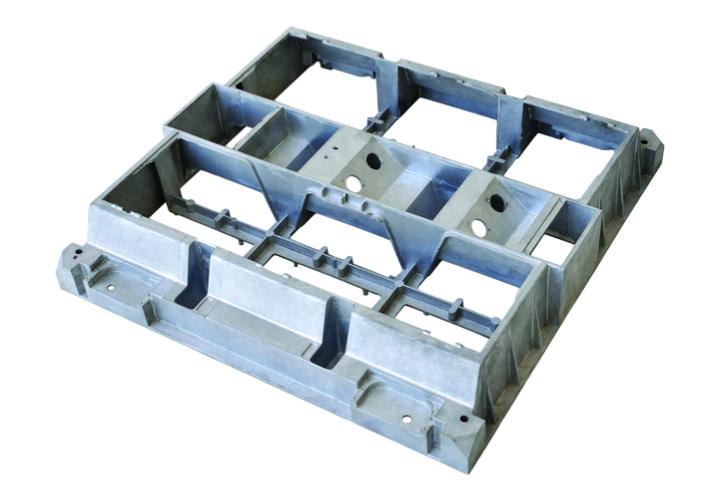

Aluminum die casting molds

Previous Page

Previous Page

05

2025-08

Daily Maintenance and Care Tips for Aluminum Die Casting Molds

02

2025-08

How zinc die casting customization services meet personalized needs

29

2025-07

How to choose a high-quality zinc die casting supplier

26

2025-07

Analysis of key factors affecting forging mold quality

22

2025-07

Research progress of forging mold repair technology

19

2025-07

Strategies to improve the service life of aluminum die casting mold

15

2025-07

Precision control methods for aluminum die casting mold

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695