26

2025

-

07

Analysis of key factors affecting forging mold quality

Author:

The quality of forging molds is directly related to the precision, quality and production efficiency of forged products. The following are several key factors affecting the quality of forging molds.

The first is the selection of mold materials. The properties of materials such as strength, hardness, toughness, heat resistance and wear resistance have a fundamental impact on mold quality. For example, high-temperature alloy materials can withstand the high temperature and high pressure environment during the forging process, reducing the deformation and softening of the mold at high temperature. If the material is not selected properly, it may cause problems such as premature cracks and wear in the mold.

Secondly, the rationality of the mold design is crucial. The design should take into account factors such as the shape of the forged part, dimensional accuracy requirements, and demolding methods. Reasonable structural design can ensure uniform stress distribution of the mold during the forging process and avoid stress concentration. For example, in the design of complex-shaped forging molds, it is necessary to carefully plan details such as the parting surface and the fillet radius of the mold cavity, otherwise the mold may be damaged due to excessive local force.

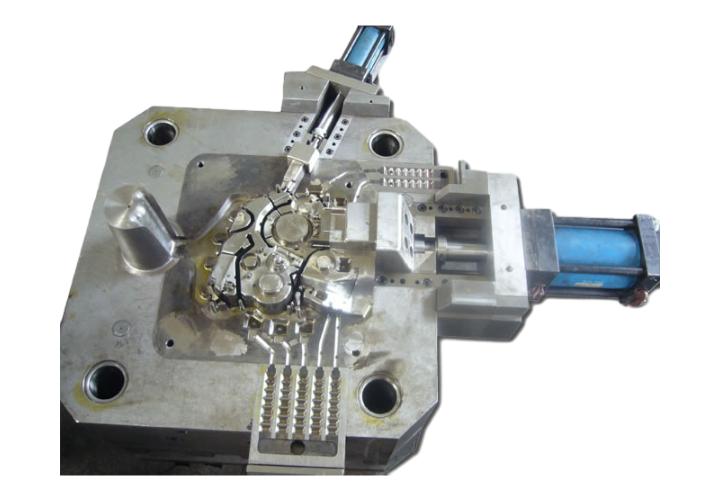

In addition, the manufacturing process level affects the quality of the mold. The processing accuracy determines the dimensional accuracy and surface quality of the mold. Advanced processing technologies such as CNC machining and EDM can accurately manufacture complex mold structures. At the same time, the heat treatment process affects the internal organization and performance of the mold. If the heat treatment is improper, problems such as uneven hardness and excessive internal residual stress will occur, reducing the quality of the mold.

Finally, the use and maintenance of the mold should not be ignored. Correct use includes operating according to the specified forging process parameters to avoid overload forging. Regular maintenance, such as cleaning, lubrication, checking wear and repairing minor damage in time, can extend the service life of the mold and maintain the stability of the mold quality. Only by fully considering these key factors can the high quality of the forging mold be ensured.

forging molds

Previous Page

Previous Page

22

2025-07

Research progress of forging mold repair technology

19

2025-07

Strategies to improve the service life of aluminum die casting mold

15

2025-07

Precision control methods for aluminum die casting mold

12

2025-07

Methods to improve the efficiency of precision aluminum casting

08

2025-07

Analysis of factors affecting the precision of precision aluminum casting

05

2025-07

Factors affecting the accuracy of aluminum die casting mold

01

2025-07

Quality control in aluminum die casting mold production

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695