22

2025

-

07

Research progress of forging mold repair technology

Author:

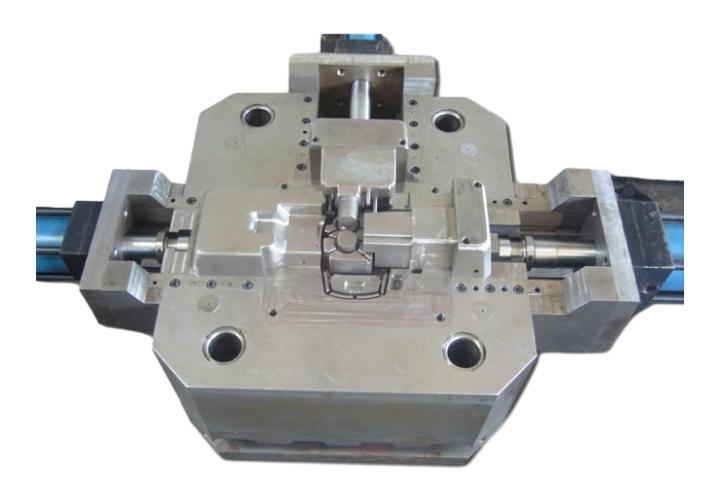

Forging mold plays a key role in the forging production process. However, due to long-term exposure to harsh working conditions such as high temperature, high pressure, and high friction, the mold is prone to wear, cracks and other damage, which highlights the importance of mold repair technology.

In terms of traditional repair technology, surfacing repair has been widely used. Forging mold accumulates welding materials on the damaged part of the mold and then performs subsequent processing to restore the size and shape of the mold. However, this method has the problem that the welding heat-affected zone may change the properties of the mold matrix, such as producing areas with excessively high or uneven hardness, affecting the overall performance of the mold.

In recent years, laser cladding repair technology has made significant progress. It uses a high-energy-density laser beam to melt the alloy powder and quickly solidify it on the damaged surface of the mold. This technology has the advantages of a small heat-affected zone, can accurately control the composition, thickness and shape of the cladding layer, and effectively improve the hardness, wear resistance and corrosion resistance of the repaired part. At the same time, laser cladding can also form a good metallurgical bond between the repair layer and the matrix, greatly improving the quality of the repaired mold.

In addition, thermal spray repair technology has also made new developments. By heating the spraying material to a molten or semi-molten state and spraying it onto the mold surface at high speed to form a coating, the mold can be repaired and the surface strengthened. New thermal spraying materials continue to emerge, making the coating performance more excellent.

With the continuous development of materials science and manufacturing technology, forging mold repair technology is developing in the direction of high precision, high performance and intelligence. These technological advances can not only extend the service life of forging molds and reduce production costs, but also promote the sustainable development of the forging industry.

Forging mold

Previous Page

Previous Page

19

2025-07

Strategies to improve the service life of aluminum die casting mold

15

2025-07

Precision control methods for aluminum die casting mold

12

2025-07

Methods to improve the efficiency of precision aluminum casting

08

2025-07

Analysis of factors affecting the precision of precision aluminum casting

05

2025-07

Factors affecting the accuracy of aluminum die casting mold

01

2025-07

Quality control in aluminum die casting mold production

29

2025-06

How to improve zinc die casting production efficiency

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695