13

2025

-

08

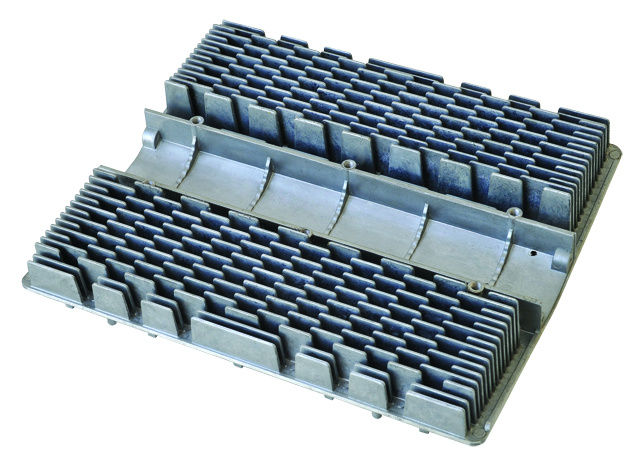

Tailored Solutions in Metal – Custom Aluminum Casting Overview

Author:

Custom aluminum casting allows manufacturers to produce parts with unique shapes, dimensions, and mechanical properties tailored to specific applications. By using specialized molds and processes such as sand casting, die casting, or investment casting, companies can achieve high precision, durability, and lightweight designs. This flexibility makes custom aluminum casting ideal for automotive, aerospace, electronics, and industrial equipment where standard components cannot meet performance requirements.

Previous Page

Previous Page

09

2025-08

How to Improve the Reusable Life of Aluminum Die Casting Molds

05

2025-08

Daily Maintenance and Care Tips for Aluminum Die Casting Molds

02

2025-08

How zinc die casting customization services meet personalized needs

29

2025-07

How to choose a high-quality zinc die casting supplier

26

2025-07

Analysis of key factors affecting forging mold quality

22

2025-07

Research progress of forging mold repair technology

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695