08

2025

-

07

Analysis of factors affecting the precision of precision aluminum casting

Author:

Precision aluminum casting has a wide range of applications in many high-end manufacturing fields, and its precision is directly related to the quality and performance of the product. The following is an analysis of factors affecting the precision of precision aluminum casting.

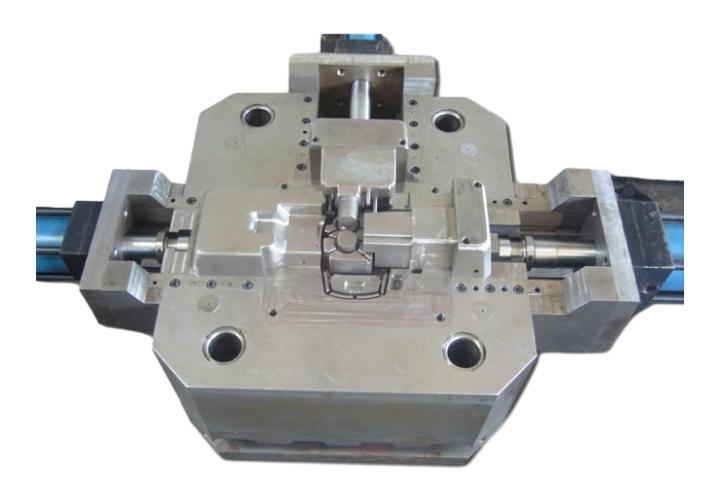

1. Mold factors

The mold is the key to precision aluminum casting. The design accuracy of the mold determines the initial shape accuracy of the casting. If the size design of the mold is inaccurate, such as the cavity size deviation, the cast aluminum part will inevitably fail to achieve the expected accuracy. At the same time, the manufacturing process of the mold is also very important. The roughness of the mold surface will affect the flow and solidification of the aluminum liquid. The rough mold surface may cause uneven flow of the aluminum liquid, which will cause deviations in the local size of the casting.

2. The nature of aluminum liquid

The temperature of the aluminum liquid has a significant effect on the accuracy. When the temperature is too high, the fluidity of the aluminum liquid is too strong, which may erode the mold, cause defects such as flash in the casting, and affect the dimensional accuracy; if the temperature is too low, the fluidity is poor, and it is easy to cause insufficient pouring, resulting in incomplete shape of the casting. The purity of aluminum liquid cannot be ignored. Excessive impurities will change the solidification characteristics of aluminum liquid, causing uneven shrinkage during solidification, thus affecting the precision.

3. Casting process parameters

Pouring speed is an important parameter. If the pouring speed is too fast, the aluminum liquid will produce turbulence in the cavity, entrain gas, cause defects such as pores, and may also cause excessive local pressure in the cavity, affecting the dimensional stability of the casting. Solidification time is also crucial. Different solidification times will lead to different shrinkage rates. Only reasonable solidification time can ensure the accuracy of casting size.

4. Environmental factors

The ambient temperature and humidity of the foundry workshop also have a certain impact on the precision of precision aluminum casting. Changes in ambient temperature may affect the heat dissipation speed of aluminum liquid, thereby affecting the solidification process and shrinkage. High humidity environment may cause aluminum liquid to absorb too much water vapor, resulting in defects such as pores that affect precision during solidification.

In summary, to improve the precision of precision aluminum casting, it is necessary to comprehensively consider mold design and manufacturing, aluminum liquid property control, process parameter optimization and environmental condition control.

Precision aluminum casting

Previous Page

Previous Page

05

2025-07

Factors affecting the accuracy of aluminum die casting mold

01

2025-07

Quality control in aluminum die casting mold production

29

2025-06

How to improve zinc die casting production efficiency

26

2025-06

Key factors affecting zinc die casting costs

22

2025-06

The role of zinc alloy for casting in industrial manufacturing

18

2025-06

Deepen your understanding of the corrosion resistance of zinc alloy for casting

14

2025-06

Discussion on post-processing technology of zinc alloy die casting

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695