05

2025

-

04

Forging Mold: A sharp tool for shaping metal

Author:

Forging mold, or forging mold, is an indispensable and important tool in the field of modern metal processing.

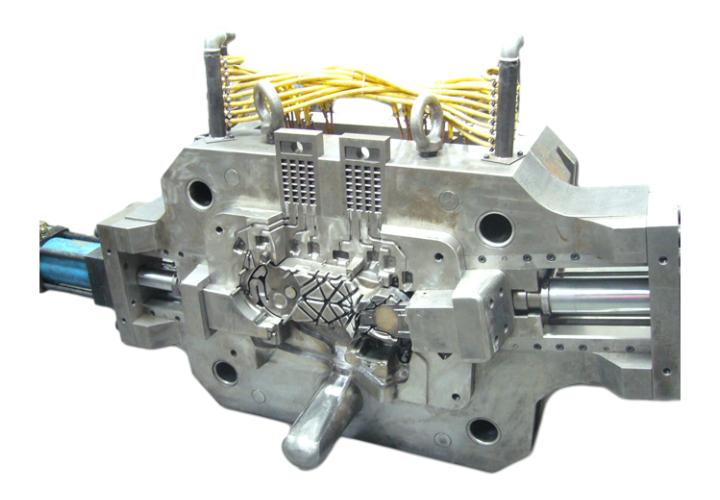

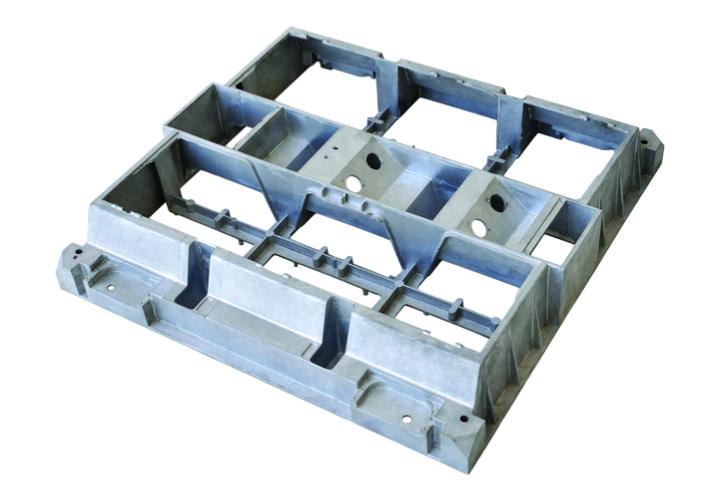

The basic principle of forging mold is to apply pressure to the metal blank to make it plastically deform in the mold cavity to obtain the desired shape and size. Its design structure is complex and exquisite. According to different forging processes and product requirements, it can be divided into various types such as open molds and closed molds. The open mold structure is relatively simple and is suitable for forging parts with simple shapes and not very high precision requirements; the closed mold can better control the flow of metal and is used to manufacture parts with complex shapes and high dimensional accuracy requirements.

In the manufacturing process of forging molds, the selection of materials is crucial. Due to the high temperature, high pressure and high friction generated during the forging process, the mold material must have good heat resistance, wear resistance and high strength. Commonly used mold materials include alloy steel, mold steel, etc. After special heat treatment process, these materials can improve their hardness, toughness and fatigue resistance.

The manufacturing accuracy of forging mold directly affects the quality of forged products. From the dimensional accuracy of the mold cavity to the surface roughness, every link needs to be strictly controlled. The application of modern technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM) makes the design and manufacture of forging molds more precise and efficient. During the production process, forging molds also need regular maintenance and repair to extend their service life. For example, the worn cavity is repaired and reprocessed to the size that meets the precision requirements.

With the continuous development of the manufacturing industry, the requirements for forging molds are also increasing. Forging mold not only needs to meet the needs of traditional industrial fields, but also needs to adapt to the needs of emerging industries such as aerospace, high-end equipment manufacturing, etc. for high-precision and high-performance forging parts, and constantly promotes metal forging technology to a higher level.

Forging mold

Previous Page

Next Page

Previous Page

Next Page

22

2025-04

Surface treatment process of aluminum die casting mold

19

2025-04

Maintenance and care tips for steel mold for aluminum casting

16

2025-04

How to optimize the structure of steel mold for aluminum casting

11

2025-04

Innovative methods to improve zinc die casting efficiency

08

2025-04

Safety precautions in zinc die casting production

05

2025-04

Forging Mold: A sharp tool for shaping metal

01

2025-04

Forging Mold: Key Tool for Metal Forming

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695