11

2025

-

04

Innovative methods to improve zinc die casting efficiency

Author:

In modern manufacturing, improving zinc die casting efficiency is crucial to the competitiveness and development of enterprises. Here are some innovative methods.

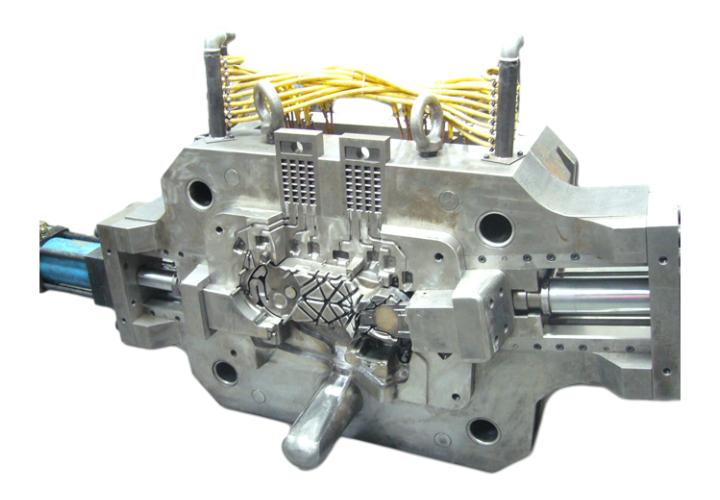

1. Optimize mold design

Advanced mold design can greatly improve zinc die casting efficiency. The multi-cavity mold design can produce multiple parts in one die casting process, thereby increasing production. At the same time, optimize the mold runner system to ensure that the zinc liquid can quickly and evenly fill the mold cavity. Reasonable gate position and size design can reduce the flow resistance of zinc liquid and increase the filling speed. For example, the use of computer simulation technology to optimize the mold runner and gate to avoid possible defects in the design stage.

2. Improve die casting equipment

New die casting equipment has great potential for improving efficiency. For example, the use of a fast mold change system can greatly shorten the mold change time. Traditional mold changes may take several hours, while the fast mold change system can shorten the time to tens of minutes or even shorter. In addition, improving the clamping force control accuracy of the die casting machine can better ensure the stability of the die casting process, reduce the defective rate, and indirectly improve production efficiency.

3. Innovation of zinc alloy materials

Develop new zinc alloy materials with better fluidity and die-castability. In this way, during the die-casting process, zinc alloy can fill the mold faster and reduce the die-casting cycle. At the same time, some new materials may have better demolding performance, reduce demolding time, and further improve overall efficiency.

4. Automation and intelligent production

Introduce automated production systems, such as robots for zinc parts pick-up, placement, and inspection. Robots can work uninterruptedly and have high operating precision. Combined with an intelligent production management system, various parameters in the die-casting process, such as temperature and pressure, are monitored in real time to promptly discover and solve potential problems and ensure efficient and continuous production. Through the comprehensive application of these innovative methods, zinc die casting companies will be able to achieve significant results in improving efficiency and occupy a favorable position in market competition.

zinc die casting

22

2025-04

Surface treatment process of aluminum die casting mold

19

2025-04

Maintenance and care tips for steel mold for aluminum casting

16

2025-04

How to optimize the structure of steel mold for aluminum casting

11

2025-04

Innovative methods to improve zinc die casting efficiency

08

2025-04

Safety precautions in zinc die casting production

05

2025-04

Forging Mold: A sharp tool for shaping metal

01

2025-04

Forging Mold: Key Tool for Metal Forming

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695