08

2025

-

04

Safety precautions in zinc die casting production

Author:

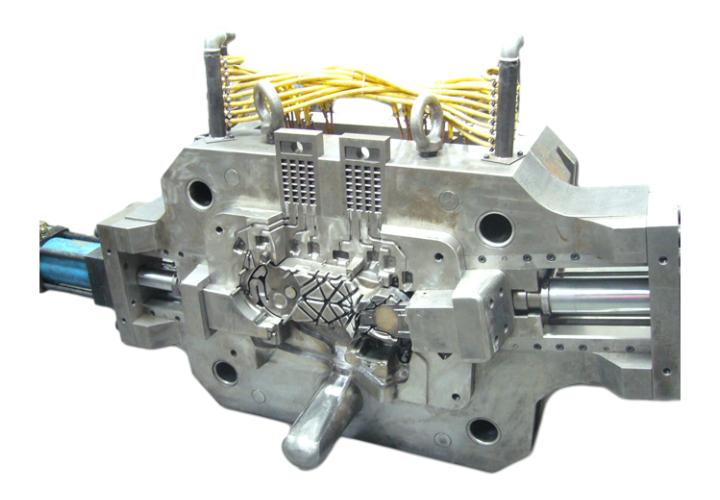

Zinc die casting production involves dangerous situations such as high temperature, high pressure and metal melting. Safety precautions must be strictly followed to ensure personnel safety and smooth production.

When the die casting machine is in operation, the operator must undergo professional training and be familiar with the operating procedures of the equipment. Before starting the die casting machine, check whether all components are normal, such as whether the hydraulic system has leakage and whether the mold is firmly installed. It is strictly forbidden to perform illegal operations when the equipment is running, such as reaching into the mold clamping area to avoid being pinched.

Zinc is in a molten state during the die casting process and the temperature is extremely high. Operators should wear high-temperature protective equipment, such as high-temperature protective clothing and protective gloves. When approaching the furnace or the workpiece that has just been die-cast, keep a safe distance to prevent high-temperature burns. At the same time, guardrails should be set around the furnace to prevent people from accidentally falling in.

Zinc dust and smoke may be generated during zinc die casting, and long-term inhalation will cause harm to the human body. The production workshop should be equipped with effective ventilation equipment to discharge dust and smoke in time. In addition, operators should wear appropriate dust masks and protective glasses to avoid dust and smoke from damaging the respiratory tract and eyes.

When replacing or repairing the mold, the mold must be cooled to a safe temperature before operation. When using tools, make sure the tools are in good condition to prevent accidents caused by damage to the tools during operation.

Safety awareness education and emergency measures are also very important. Enterprises should conduct safety training for employees regularly to improve their safety awareness. At the same time, the workshop should be equipped with necessary fire extinguishing equipment, first aid medicines, etc., and a complete emergency plan should be formulated so that it can respond quickly when an emergency occurs and minimize losses.

Zinc die casting

22

2025-04

Surface treatment process of aluminum die casting mold

19

2025-04

Maintenance and care tips for steel mold for aluminum casting

16

2025-04

How to optimize the structure of steel mold for aluminum casting

11

2025-04

Innovative methods to improve zinc die casting efficiency

08

2025-04

Safety precautions in zinc die casting production

05

2025-04

Forging Mold: A sharp tool for shaping metal

01

2025-04

Forging Mold: Key Tool for Metal Forming

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695