01

2025

-

04

Forging Mold: Key Tool for Metal Forming

Author:

Forging mold plays a pivotal role in the field of modern metal processing.

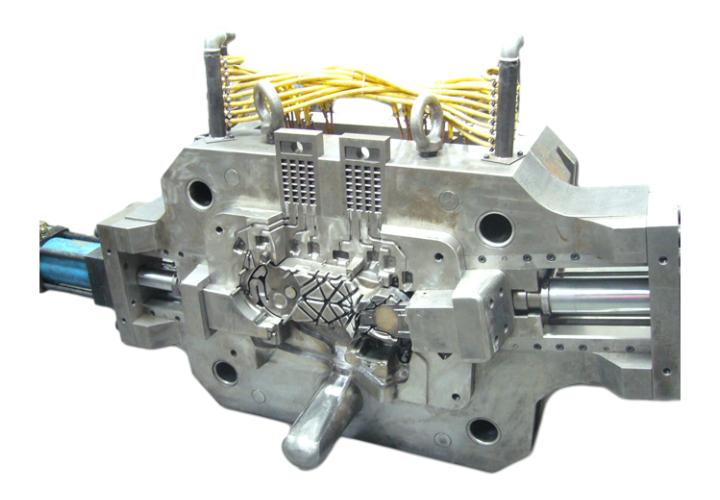

Forging mold is a tool used to process metal materials into the desired shape and size through forging process. From a structural point of view, Forging Mold has a high degree of precision. The design of its cavity corresponds precisely to the shape of the final product. Whether it is a complex mechanical part or a simple metal component, the forging mold can be realized through reasonable structural design. For example, when manufacturing key parts of automobile engines, forging molds can accurately shape high-temperature metal billets into shapes that meet strict tolerance requirements.

In terms of material selection, forging molds need to use materials with high strength, high heat resistance and high wear resistance. This is because during the forging process, the mold needs to withstand huge pressure and high temperature. High-quality mold materials can ensure that the mold can still maintain the accuracy of its cavity after multiple forging cycles, thereby ensuring the stability of product quality.

The manufacturing process of Forging mold is also a technology-intensive link. From the initial design modeling, advanced computer-aided design (CAD) software is needed to accurately plan the shape and size of the mold. Then, the design is transformed into an actual mold through precision processing techniques such as CNC machining. After the forging mold is manufactured, it also needs to undergo strict quality inspections, including dimensional accuracy inspections, surface roughness inspections, etc.

In industrial production, the quality of Forging Mold directly affects the quality, production efficiency and cost of forged products. High-quality forging molds can improve production efficiency, reduce scrap rates, and reduce energy consumption. With the continuous development of modern industry, the performance requirements for forging molds are also constantly increasing, and forging mold technology is also continuously innovating to meet the growing industrial needs.

Forging mold

Previous Page

Next Page

Previous Page

Next Page

22

2025-04

Surface treatment process of aluminum die casting mold

19

2025-04

Maintenance and care tips for steel mold for aluminum casting

16

2025-04

How to optimize the structure of steel mold for aluminum casting

11

2025-04

Innovative methods to improve zinc die casting efficiency

08

2025-04

Safety precautions in zinc die casting production

05

2025-04

Forging Mold: A sharp tool for shaping metal

01

2025-04

Forging Mold: Key Tool for Metal Forming

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695