19

2025

-

04

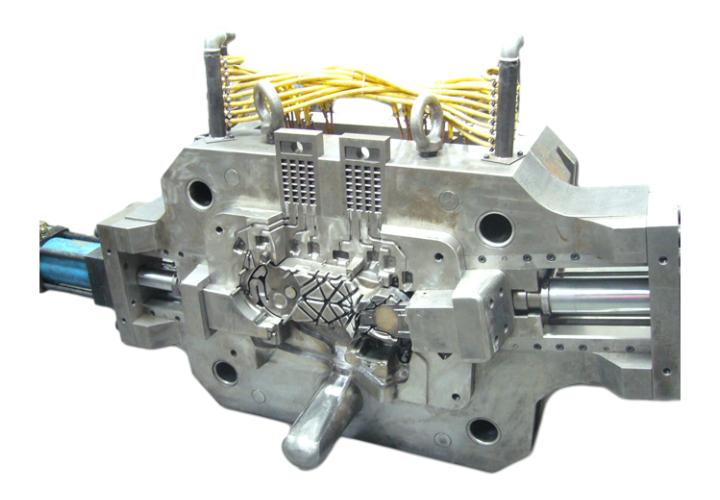

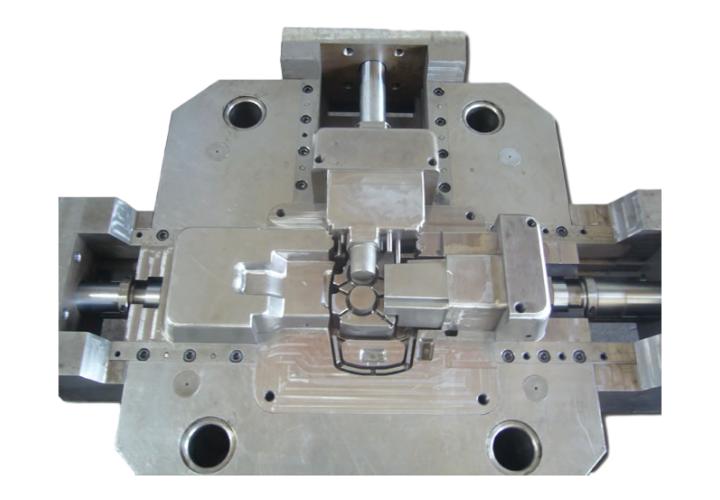

Maintenance and care tips for steel mold for aluminum casting

Author:

Steel mold for aluminum casting plays a key role in casting production. Good maintenance and care can extend its service life and ensure casting quality.

First of all, the mold must be thoroughly cleaned after each use. During the aluminum casting process, aluminum liquid may remain in the mold cavity, runner and other parts. Use special cleaning tools, such as soft scrapers, to carefully remove these residual aluminum chips to avoid scratching the mold surface. For some corners that are difficult to clean, you can use compressed air to blow or suitable solvents to clean, but be careful that the solvent cannot corrode the mold steel.

Secondly, check the wear of the mold regularly. Focus on checking whether the surface of the cavity is worn, corroded or deformed. If slight wear is found, it can be repaired by grinding, polishing and other methods to restore the finish of the cavity. For severely worn parts, repair measures such as repair welding and recasting may be required, and the dimensional accuracy after repair must meet the requirements.

In addition, lubrication of steel mold for aluminum casting is also very important. Before closing the mold, apply an appropriate amount of lubricant to the moving parts of the mold, such as the slider, ejector mechanism, etc., to reduce friction and ensure smooth movement of the parts. At the same time, the lubricant can also play a certain anti-rust role.

The storage of steel mold for aluminum casting should not be ignored. When storing, choose a dry and well-ventilated environment to prevent the mold from getting damp and rusting. If the storage time is long, you can apply a layer of anti-rust oil on the surface of the mold and wrap it with anti-rust paper or plastic film to prevent dust and corrosive gases from corroding the mold.

In addition, the cooling system of steel mold for aluminum casting should be maintained regularly. Check whether the cooling pipe is blocked or leaking to ensure the normal circulation of the coolant, which is crucial to controlling the mold temperature, ensuring the casting quality and the life of the mold.

Steel mold for aluminum casting

Previous Page

22

2025-04

Surface treatment process of aluminum die casting mold

19

2025-04

Maintenance and care tips for steel mold for aluminum casting

16

2025-04

How to optimize the structure of steel mold for aluminum casting

11

2025-04

Innovative methods to improve zinc die casting efficiency

08

2025-04

Safety precautions in zinc die casting production

05

2025-04

Forging Mold: A sharp tool for shaping metal

01

2025-04

Forging Mold: Key Tool for Metal Forming

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695