26

2025

-

04

Precision control in aluminum die casting mold manufacturing

Author:

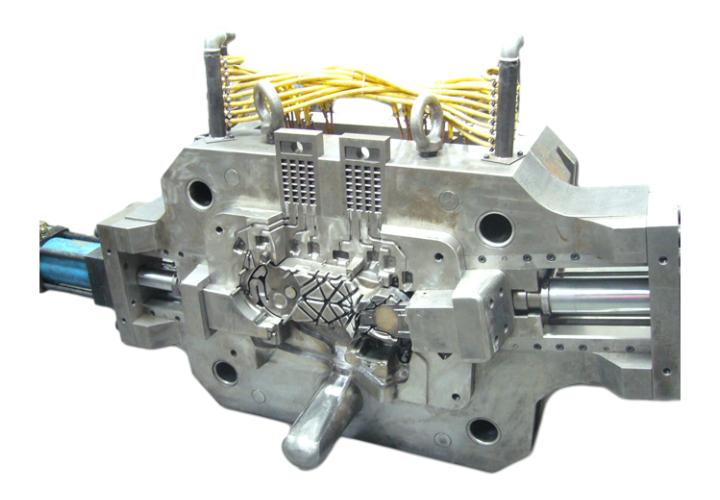

In aluminum die casting mold manufacturing, precision control is a key factor in ensuring mold quality and die-casting product quality.

First, precision considerations in the design stage are the basis. Designers need to accurately plan the structure, size and tolerance range of the mold. For aluminum die casting molds, the dimensional accuracy of the cavity directly affects the shape accuracy of the die-casting product. Even a small design error will be magnified in the subsequent die-casting process, resulting in product dimensions that do not meet requirements or defects such as flash and lack of material. For example, when designing a die-casting mold with a complex internal structure, the wall thickness and demolding slope of each part must be accurately calculated to ensure that the aluminum liquid can smoothly fill the cavity and does not damage the product during demolding.

In the processing and manufacturing process, the application of CNC machine tools plays an important role in precision control. Through CNC programming, the path and cutting parameters of the tool can be accurately controlled. When processing the core and cavity of the mold, the processing accuracy must reach the micron level. This requires regular calibration and maintenance of CNC machine tools to ensure their motion accuracy and positioning accuracy. For example, when milling the mold surface, precise control of the tool speed, feed rate and cutting depth can effectively reduce processing errors and make the mold surface reach the required roughness and shape accuracy.

The aluminum die casting mold assembly process also requires strict precision control. The assembly accuracy of each component is directly related to the overall performance of the mold. For example, the assembly of the movable mold and the fixed mold must ensure the accuracy of their mold closing, and the gap must be uniform and consistent, otherwise aluminum liquid leakage or uneven pressure will occur during die casting. This requires assembly workers to use high-precision measuring tools for measurement and adjustment, such as micrometers, three-coordinate measuring machines, etc., to ensure that each component is installed in the correct position and achieve the assembly accuracy required by the design.

aluminum die casting mold china

Previous Page

Previous Page

22

2025-04

Surface treatment process of aluminum die casting mold

19

2025-04

Maintenance and care tips for steel mold for aluminum casting

16

2025-04

How to optimize the structure of steel mold for aluminum casting

11

2025-04

Innovative methods to improve zinc die casting efficiency

08

2025-04

Safety precautions in zinc die casting production

05

2025-04

Forging Mold: A sharp tool for shaping metal

01

2025-04

Forging Mold: Key Tool for Metal Forming

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695