13

2025

-

05

How to ensure the quality of forging mold

Author:

The quality of forging mold is directly related to the quality, production efficiency and cost of forging products. To ensure the quality of forging mold, we need to start from many aspects.

First of all, the selection of materials is crucial. The appropriate mold material should be selected according to the use requirements of forging mold, such as the pressure, temperature, wear degree, etc. For example, for forging molds that are subjected to high pressure and high temperature, it is necessary to select materials with high hardness, high strength and good heat resistance. High-quality materials are the basis for ensuring mold quality and determine the upper limit of mold performance from the source.

Secondly, the manufacturing process must be precise. In the manufacturing process of the mold, whether it is machining, heat treatment or surface treatment, every link must be strictly carried out in accordance with the standard process. For example, during machining, dimensional accuracy must be guaranteed. Even a small error may affect the mold fitting accuracy, resulting in problems such as flash and dimensional deviation in forged products. The heat treatment process can improve the internal organization of the mold and improve its comprehensive performance, so parameters such as heating temperature, insulation time and cooling speed must be strictly controlled.

In addition, the quality inspection link is indispensable. During the mold manufacturing process, multiple rounds of testing are required. For example, non-destructive testing technology is used to detect whether there are defects such as cracks inside, and precision testing tools are used to ensure the dimensional accuracy of the mold. For surface quality, roughness, hardness uniformity, etc. must be checked. Only when each test indicator is qualified can the quality of the entire mold be guaranteed.

Finally, the use and maintenance of the mold will also affect its quality. During use, it is necessary to operate in accordance with the operating procedures to avoid overload. At the same time, regular maintenance of the mold, timely cleaning of dirt and repair of worn parts can extend the service life of the mold and ensure its stable quality throughout its service life.

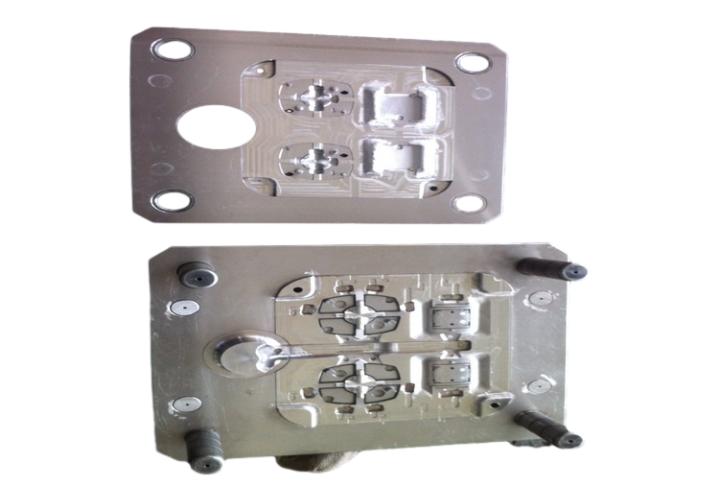

forging mold

Previous Page

08

2025-06

Zinc die casting has special requirements for mold design

05

2025-06

Explore the wide application of zinc die casting in industrial production

31

2025-05

In-depth analysis of common faults and maintenance of metal stamping mold

27

2025-05

Analysis of key points in the structural design of metal stamping mold

23

2025-05

Explore the design secrets of aluminum die casting mold

20

2025-05

Analysis of factors affecting the molding quality of aluminum die casting mold

16

2025-05

Application of forging mold in automobile manufacturing

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695