16

2025

-

05

Application of forging mold in automobile manufacturing

Author:

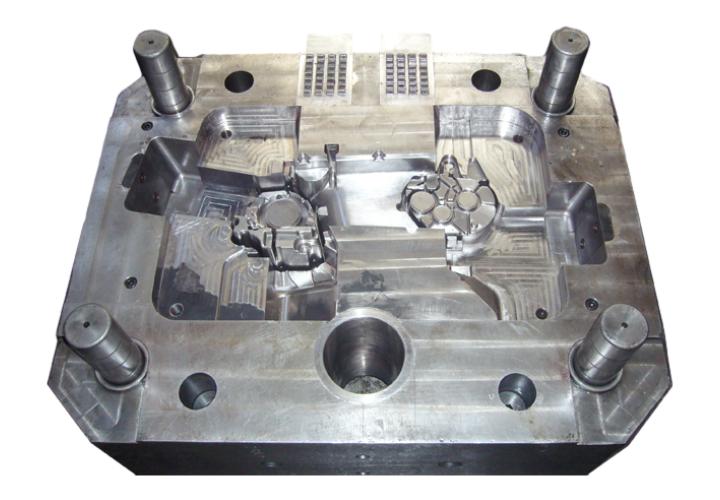

In the field of automobile manufacturing, forging mold plays an indispensable and important role.

There are many parts in the car that need to have the characteristics of high strength and high reliability, and the forging process can meet this demand, and forging mold is the key to realizing this process. For example, the key parts of the car crankshaft, connecting rod, etc., through the action of forging mold, can make the metal material plastically deform under pressure, thereby obtaining a dense organizational structure. Forging mold can precisely control the shape and size of these parts and ensure that their accuracy is within a strict tolerance range.

In the manufacture of automobile engines, forging mold is widely used in the production of pistons, valves and other parts. During the forging process, the mold gives the metal material a specific pressure and deformation mode, so that these parts have excellent mechanical properties, such as high tensile strength and fatigue strength. This helps to improve the overall performance and reliability of the engine and extend its service life.

Forging mold is also of great significance for some parts of the automobile chassis, such as steering knuckles. The steering knuckle made by forging mold has a more stable structure and can withstand greater stress under complex road conditions without deformation or damage, ensuring the safety of automobile driving.

At the same time, with the continuous development of automobile manufacturing technology, forging mold is also constantly innovating. Advanced forging mold design and manufacturing technology can improve production efficiency and reduce production costs. For example, the use of multi-station forging mold can complete multiple forging processes on one mold, reducing processing time and equipment investment. Moreover, high-precision forging mold can reduce subsequent processing steps and further improve production efficiency. In short, forging mold is one of the key factors in improving automobile quality and performance in automobile manufacturing.

forging mold

08

2025-06

Zinc die casting has special requirements for mold design

05

2025-06

Explore the wide application of zinc die casting in industrial production

31

2025-05

In-depth analysis of common faults and maintenance of metal stamping mold

27

2025-05

Analysis of key points in the structural design of metal stamping mold

23

2025-05

Explore the design secrets of aluminum die casting mold

20

2025-05

Analysis of factors affecting the molding quality of aluminum die casting mold

16

2025-05

Application of forging mold in automobile manufacturing

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695