13

2025

-

10

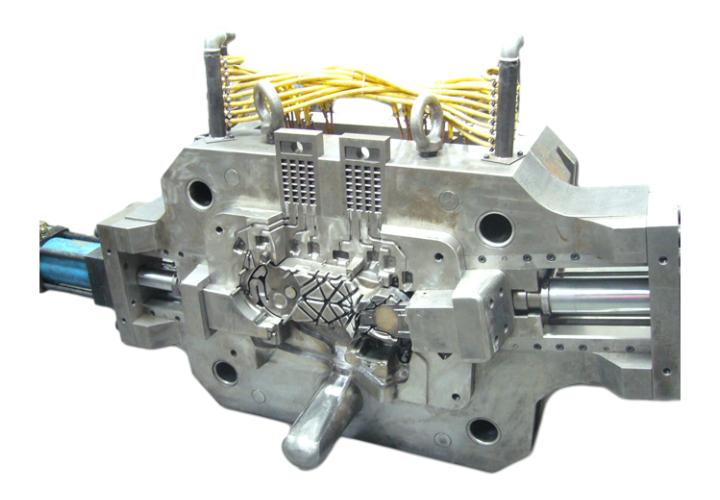

Understanding Aluminum Alloy Molds: A Key Component in Precision Manufacturing

Author:

One of the primary benefits of aluminum alloy molds lies in their ability to produce high-quality parts with exceptional detail. The aluminum's inherent properties allow for precise dimensional tolerances, which is critical in industries that require exact specifications. When combined with advanced machining techniques, aluminum alloy molds can achieve complex geometries and intricate designs that are often challenging to create with other materials. This precision is essential in sectors such as automotive, aerospace, and consumer electronics, where even minor deviations can lead to significant performance issues.

Another key advantage of aluminum alloy molds is their superior thermal conductivity. This property facilitates efficient heat dissipation during the molding process, which is vital for maintaining consistent material flow and reducing cycle times. By ensuring that the mold temperature remains stable, manufacturers can enhance the quality of the final product while optimizing production efficiency. This aspect is particularly beneficial in high-volume production settings, where time and consistency are paramount.

Additionally, aluminum alloys offer excellent corrosion resistance, which extends the lifespan of molds and reduces maintenance costs. In environments where moisture and various chemicals are present, the durability of aluminum alloy molds becomes a significant asset. They are less prone to rust and degradation compared to steel molds, thereby ensuring a longer operational life and sustained performance over time.

The versatility of aluminum alloys also allows for various modifications and treatments to enhance their properties further. For example, surface treatments can be applied to improve hardness or wear resistance, making aluminum molds suitable for a broader range of applications. This adaptability is crucial for manufacturers looking to meet diverse market demands without investing in entirely new tooling systems.

In summary, aluminum alloy molds represent a critical component in the realm of precision manufacturing. Their lightweight nature, excellent thermal properties, and corrosion resistance make them an ideal choice for producing high-quality components efficiently. As industries continue to evolve and emphasize the importance of precision and reliability, the role of aluminum alloy molds will undoubtedly become even more significant in the future of manufacturing processes. Understanding these molds' capabilities and advantages can empower professionals to make informed decisions, leading to enhanced productivity and quality in their operations.

Aluminum alloy mold

28

2025-10

Elevating Quality Standards: The Role of Aluminum Casting in Mechanical Processing

25

2025-10

22

2025-10

Efficiency Redefined: Advancements in Zinc Die Casting for Molding

19

2025-10

Understanding Die Casting Machines: An Essential Guide for Metalworking Professionals

16

2025-10

Unleashing the Potential of Aluminum Die Casting in Modern Manufacturing

13

2025-10

Understanding Aluminum Alloy Molds: A Key Component in Precision Manufacturing

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695