31

2025

-

10

Understanding Die Casting Molds: Key Insights for Professionals in the Manufacturing Industry

Author:

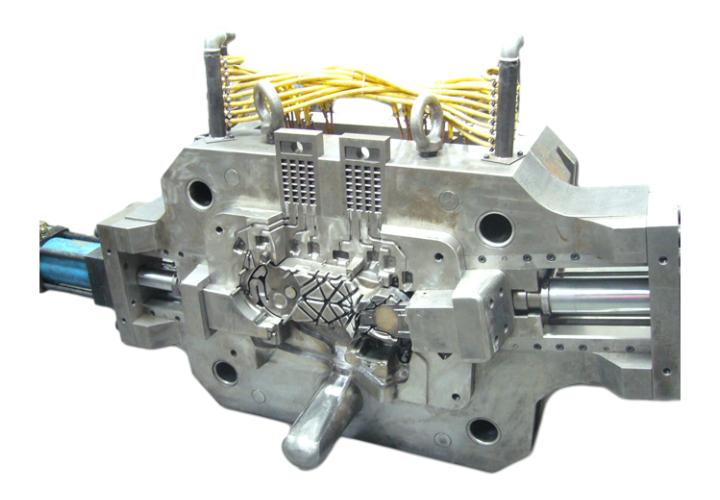

The design of die casting molds typically involves two halves, known as the "core" and "cavity." The core forms the internal features of the component, while the cavity shapes the external surfaces. A well-designed mold can significantly enhance production efficiency by minimizing defects and ensuring uniformity in the final product. Key design considerations include the mold's cooling system, which affects cooling rates and cycle times, and the incorporation of ejector pins to facilitate the removal of the cast part.

Materials play a critical role in the performance and durability of die casting molds. Common materials used include high-strength steels, aluminum alloys, and beryllium-copper. Each material has its own advantages and is chosen based on factors such as thermal conductivity, resistance to wear, and overall cost-effectiveness. For instance, beryllium-copper is known for its excellent thermal properties, making it suitable for molds requiring rapid cooling.

The manufacturing process of die casting molds involves several stages, including machining, surface treatment, and assembly. Precision machining is essential to achieve the desired tolerances and surface finishes. Advanced techniques, such as Computer Numerical Control (CNC) machining, have greatly improved the accuracy and repeatability of mold fabrication, enabling manufacturers to produce complex geometries with tight tolerances.

In addition to the technical aspects, understanding the application of die casting molds is vital. These molds are commonly used in industries such as automotive, aerospace, and consumer electronics, where high-volume production and intricate designs are required. The versatility of die casting molds allows them to be used for a wide range of components, from small intricate parts to larger structural components.

Lastly, maintaining die casting molds is crucial for ensuring their longevity and performance. Regular inspection and maintenance can prevent common issues, such as wear and tear, which can lead to production downtimes and increased costs. Implementing a robust maintenance schedule can help identify potential problems early and ensure that molds remain in optimal working condition.

In conclusion, die casting molds are a cornerstone of efficient manufacturing processes in various industries. By understanding the design, materials, and maintenance of these molds, professionals can improve their production capabilities and enhance the quality of their outputs. As the demand for precision-engineered components continues to grow, investing in high-quality die casting molds will remain a key factor in achieving manufacturing excellence.

die casting mold

Previous Page

Previous Page

28

2025-10

Elevating Quality Standards: The Role of Aluminum Casting in Mechanical Processing

25

2025-10

22

2025-10

Efficiency Redefined: Advancements in Zinc Die Casting for Molding

19

2025-10

Understanding Die Casting Machines: An Essential Guide for Metalworking Professionals

16

2025-10

Unleashing the Potential of Aluminum Die Casting in Modern Manufacturing

13

2025-10

Understanding Aluminum Alloy Molds: A Key Component in Precision Manufacturing

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695