16

2025

-

10

Unleashing the Potential of Aluminum Die Casting in Modern Manufacturing

Author:

Unleashing the Potential of Aluminum Die Casting in Modern Manufacturing

Table of Contents

1. Introduction to Aluminum Die Casting

2. The Process of Aluminum Die Casting

2.1 Types of Die Casting Processes

2.2 Key Steps in the Die Casting Process

3. Advantages of Aluminum Die Casting

3.1 Cost-Effectiveness and Efficiency

3.2 Enhanced Mechanical Properties

4. Applications of Aluminum Die Casting in Various Industries

4.1 Automotive Industry

4.2 Aerospace Industry

4.3 Consumer Electronics

5. Challenges in Aluminum Die Casting

6. Innovations and Future Trends in Aluminum Die Casting

7. Frequently Asked Questions (FAQs)

8. Conclusion

1. Introduction to Aluminum Die Casting

Aluminum die casting is a manufacturing process that involves forcing molten aluminum into a mold cavity under high pressure. This technique has gained immense popularity due to its ability to produce complex shapes with exceptional accuracy and surface finish. As industries continue to seek ways to enhance productivity and reduce material costs, aluminum die casting emerges as a reliable solution that meets these demands.

2. The Process of Aluminum Die Casting

Understanding the aluminum die casting process is crucial for manufacturers seeking to leverage its benefits.

2.1 Types of Die Casting Processes

There are primarily two types of die casting processes: **hot chamber die casting** and **cold chamber die casting**.

- **Hot Chamber Die Casting**: This method is suitable for alloys with low melting points. The process involves a machine where the molten metal is held in a chamber and injected directly into the die cavity. It’s efficient for high production volumes.

- **Cold Chamber Die Casting**: Often used for high-melting-point alloys like aluminum, this process involves pouring the molten metal into a separate chamber before injection. Although it is slower than hot chamber die casting, it is ideal for producing larger and more intricate parts.

2.2 Key Steps in the Die Casting Process

The aluminum die casting process typically involves several key steps:

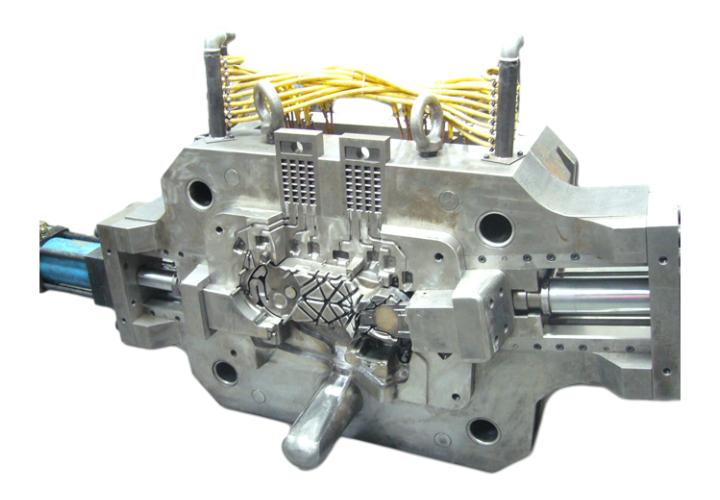

1. **Mold Preparation**: The dies are meticulously designed and manufactured, ensuring precision and durability.

2. **Metal Melting**: Aluminum is heated in a furnace until it reaches a molten state.

3. **Injection**: The molten aluminum is injected into the mold under high pressure, filling the cavity.

4. **Cooling**: The metal cools rapidly, solidifying into the desired shape.

5. **Ejection**: Once cooled, the die opens, and the finished part is ejected.

6. **Trimming and Finishing**: Excess material is trimmed, and finishing processes may be applied to achieve the desired surface quality.

3. Advantages of Aluminum Die Casting

The popularity of aluminum die casting can be attributed to its numerous advantages.

3.1 Cost-Effectiveness and Efficiency

Aluminum die casting offers significant cost savings, particularly in high-volume production runs. The speed of the casting process allows manufacturers to produce large quantities of parts in a short amount of time, thus reducing labor and operational costs.

3.2 Enhanced Mechanical Properties

Aluminum die-cast components exhibit excellent mechanical properties, including high strength-to-weight ratios, corrosion resistance, and good thermal conductivity. These characteristics make aluminum die casting an attractive option for industries that require reliable and durable components.

4. Applications of Aluminum Die Casting in Various Industries

Aluminum die casting finds applications across a wide range of industries, each benefiting from its unique properties.

4.1 Automotive Industry

In the automotive sector, aluminum die casting is used to manufacture critical components such as engine blocks, transmission cases, and wheels. The lightweight nature of aluminum helps improve fuel efficiency while maintaining structural integrity.

4.2 Aerospace Industry

The aerospace industry leverages aluminum die casting to produce lightweight and robust components essential for aircraft performance. Components such as brackets, housings, and structural parts benefit from the precision and consistency offered by die casting.

4.3 Consumer Electronics

In consumer electronics, aluminum die-cast parts are prevalent in devices such as smartphones, laptops, and gaming consoles. The aesthetic finish and thermal management properties of aluminum enhance product design and functionality.

5. Challenges in Aluminum Die Casting

Despite its advantages, aluminum die casting is not without challenges. These may include:

- **Complexity in Design**: Designing for die casting requires specialized knowledge to avoid potential defects.

- **Initial Tooling Costs**: The upfront investment for high-quality molds can be significant, impacting smaller manufacturers.

- **Defects**: Issues like porosity, cold shuts, and other casting defects can arise if not properly managed.

6. Innovations and Future Trends in Aluminum Die Casting

The aluminum die casting industry is evolving with technological advancements, including:

- **Additive Manufacturing**: Integrating 3D printing with die casting processes is paving the way for more complex designs and shorter lead times.

- **Smart Casting Technologies**: Utilizing sensors and automation enhances precision and efficiency in the casting process.

- **Sustainability Efforts**: As industries move towards sustainability, processes are being optimized to reduce waste and recycle materials effectively.

7. Frequently Asked Questions (FAQs)

Q1: What is the difference between hot and cold chamber die casting?

A1: Hot chamber die casting uses a chamber where molten metal is injected directly, suitable for low melting point alloys. Cold chamber die casting involves pouring molten metal into a chamber before injection, ideal for high-melting-point materials like aluminum.

Q2: What are the main advantages of using aluminum in die casting?

A2: Aluminum offers a high strength-to-weight ratio, corrosion resistance, excellent thermal conductivity, and cost-effectiveness, making it ideal for various applications.

Q3: Is aluminum die casting environmentally friendly?

A3: Aluminum die casting can be environmentally friendly, especially when recycling is incorporated into the manufacturing process, significantly reducing waste.

Q4: How does the die casting process affect the final product's quality?

A4: The die casting process significantly impacts the product's quality by ensuring precise dimensions, excellent surface finishes, and enhanced mechanical properties when executed correctly.

Q5: Can aluminum die casting be used for intricate designs?

A5: Yes, aluminum die casting is suitable for intricate designs, allowing manufacturers to produce complex shapes with tight tolerances.

8. Conclusion

Aluminum die casting stands at the forefront of modern manufacturing, driving innovation and efficiency across various industries. Its ability to produce high-quality components at scale while reducing costs makes it an invaluable process in today's competitive market. As technology continues to evolve, aluminum die casting will undoubtedly play a pivotal role in shaping the future of manufacturing, offering unparalleled opportunities for advancement and sustainability. Embracing this potential can lead to a more efficient, reliable, and innovative manufacturing landscape.

aluminum die casting

28

2025-10

Elevating Quality Standards: The Role of Aluminum Casting in Mechanical Processing

25

2025-10

22

2025-10

Efficiency Redefined: Advancements in Zinc Die Casting for Molding

19

2025-10

Understanding Die Casting Machines: An Essential Guide for Metalworking Professionals

16

2025-10

Unleashing the Potential of Aluminum Die Casting in Modern Manufacturing

13

2025-10

Understanding Aluminum Alloy Molds: A Key Component in Precision Manufacturing

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695