25

2025

-

10

Understanding Zinc Casting: A Comprehensive Overview for Professionals in the Manufacturing and Tooling Industry

Author:

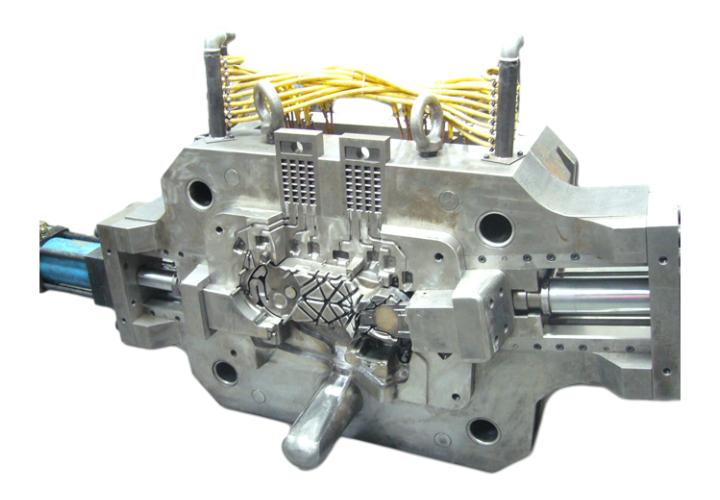

One of the most significant benefits of zinc casting is its ability to produce intricate designs with tight tolerances. Zinc alloys, such as ZA-8, ZA-12, and ZA-27, have excellent fluidity, enabling them to fill molds completely and capture fine details. This characteristic not only enhances the aesthetic appeal of the final products but also ensures that they meet stringent engineering specifications.

Another notable advantage of zinc casting is the material's inherent properties. Zinc is known for its corrosion resistance, making it an ideal choice for components exposed to harsh environments. Additionally, zinc castings exhibit good dimensional stability, which is crucial for maintaining the integrity of parts in demanding applications. The process allows for a relatively short lead time, making it suitable for both small-scale production and high-volume manufacturing.

Zinc casting is also environmentally friendly. The process generates less waste compared to other metal casting methods, and zinc is 100% recyclable. Recycled zinc maintains its properties and can be reused without significant degradation in quality, contributing to sustainability in manufacturing practices.

In terms of applications, zinc casting is utilized in producing components such as housings, brackets, and connectors. Industries that benefit from zinc castings include automotive, where parts need to withstand mechanical stresses, and electronics, where precision and reliability are critical. Furthermore, the lightweight nature of zinc castings makes them ideal for reducing the overall weight of products, thereby improving energy efficiency in applications like vehicles.

As professionals in the manufacturing and tooling industry, understanding zinc casting's capabilities can greatly enhance your operations. The ability to produce high-quality, precision components efficiently opens up new opportunities for innovation and design. By leveraging the advantages of zinc casting, manufacturers can respond to market demands with agility and creativity.

In conclusion, zinc casting is a versatile and efficient manufacturing process that offers numerous benefits, including high precision, corrosion resistance, and environmental sustainability. By exploring its applications and advantages, professionals can better integrate this technique into their production strategies, resulting in enhanced product offerings and competitive advantage in the market.

zinc casting

28

2025-10

Elevating Quality Standards: The Role of Aluminum Casting in Mechanical Processing

25

2025-10

22

2025-10

Efficiency Redefined: Advancements in Zinc Die Casting for Molding

19

2025-10

Understanding Die Casting Machines: An Essential Guide for Metalworking Professionals

16

2025-10

Unleashing the Potential of Aluminum Die Casting in Modern Manufacturing

13

2025-10

Understanding Aluminum Alloy Molds: A Key Component in Precision Manufacturing

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695