22

2025

-

10

Efficiency Redefined: Advancements in Zinc Die Casting for Molding

Author:

Efficiency Redefined: Advancements in Zinc Die Casting for Molding

Table of Contents

- 1. Introduction to Zinc Die Casting

- 2. Benefits of Zinc Die Casting in Manufacturing

- 3. Latest Technology Advancements in Zinc Die Casting

- 4. Environmental Impact and Sustainability

- 5. Quality Control Measures in Zinc Die Casting

- 6. Industry Applications of Zinc Die Casting

- 7. Future Trends in Zinc Die Casting

- 8. FAQs About Zinc Die Casting

- 9. Conclusion: The Future of Zinc Die Casting

1. Introduction to Zinc Die Casting

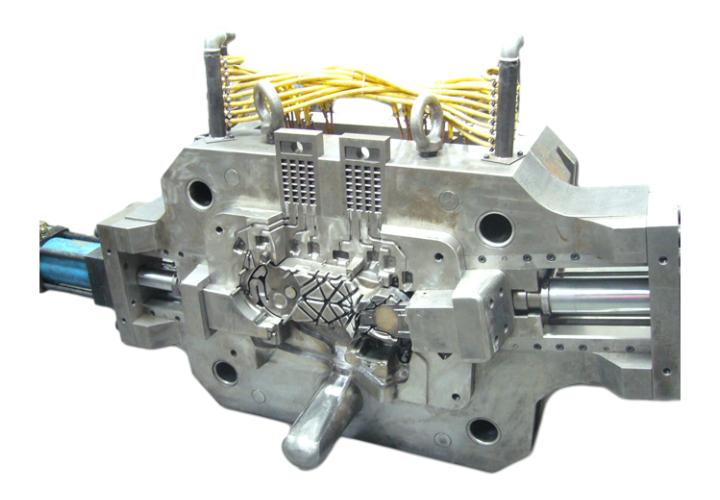

Zinc die casting is a highly efficient manufacturing process that involves the injection of molten zinc into a mold to create precise and complex parts. This method stands out for its ability to produce high-quality components with excellent surface finishes. As industries seek faster production times and reduced costs, zinc die casting has emerged as a preferred choice in various sectors, including automotive, electronics, and consumer goods.

The process begins with heating zinc to its melting point and then injecting it under high pressure into a mold cavity. This process not only ensures high dimensional accuracy but also facilitates rapid production cycles, making it ideal for mass production.

2. Benefits of Zinc Die Casting in Manufacturing

The adoption of zinc die casting offers numerous advantages that significantly enhance manufacturing efficiency and product quality.

2.1 Cost-Effectiveness

Zinc die casting provides a cost-effective solution for producing high volumes of parts. The initial investment in molds may be higher, but the long-term savings from reduced material waste, shortened cycle times, and lower labor costs make it economically advantageous.

2.2 Exceptional Mechanical Properties

Zinc alloys possess excellent mechanical properties, such as high strength, good ductility, and superior corrosion resistance. These characteristics make zinc die-cast components suitable for demanding applications, ensuring longevity and reliability.

2.3 Precision and Detail

The ability to create intricate designs with high dimensional accuracy is one of the standout features of zinc die casting. This precision minimizes the need for secondary machining, further reducing production costs and time.

3. Latest Technology Advancements in Zinc Die Casting

Recent advancements in zinc die casting technology have revolutionized the manufacturing landscape.

3.1 Automation and Robotics

The integration of automation and robotics in zinc die casting processes enhances efficiency, precision, and safety. Automated systems streamline operations, reduce human error, and facilitate quicker turnaround times.

3.2 3D Printing for Mold Creation

The use of 3D printing technology for creating molds allows for rapid prototyping and testing. This innovation enables manufacturers to refine designs quickly and reduce lead times significantly.

3.3 Enhanced Materials

Advancements in alloy compositions have led to the development of zinc alloys that offer improved performance characteristics. These include enhanced thermal properties, better fluidity, and increased strength, further pushing the boundaries of what can be achieved through zinc die casting.

4. Environmental Impact and Sustainability

As sustainability becomes a core focus for industries worldwide, zinc die casting plays a pivotal role in reducing environmental impact.

4.1 Recyclability of Zinc

Zinc is one of the most recycled metals globally, with recycling processes consuming significantly less energy compared to primary zinc production. This characteristic aligns with the growing emphasis on sustainable manufacturing practices.

4.2 Reduced Waste Generation

The precision of zinc die casting leads to minimal waste generation during production. The process maximizes material usage, and any excess zinc can be collected and reused, further contributing to sustainability efforts.

5. Quality Control Measures in Zinc Die Casting

Ensuring the quality of zinc die-cast components is paramount in maintaining industry standards and customer satisfaction.

5.1 In-Process Monitoring

Real-time monitoring during the die casting process helps identify issues early on, allowing for immediate corrective actions. This proactive approach minimizes defects and enhances product quality.

5.2 Testing and Inspection Protocols

Comprehensive testing and inspection protocols, including dimensional checks and mechanical property evaluations, are critical in guaranteeing that each component meets rigorous quality standards.

6. Industry Applications of Zinc Die Casting

The versatility of zinc die casting makes it applicable across various industries.

6.1 Automotive Industry

In the automotive sector, zinc die casting is utilized for producing components such as transmission housings, engine brackets, and decorative trim parts. The combination of strength and lightweight characteristics makes zinc an ideal choice for automotive applications.

6.2 Electronics Sector

Zinc die casting finds extensive use in the electronics industry for manufacturing housings, connectors, and heat sinks. The excellent thermal conductivity of zinc alloys ensures efficient heat dissipation, enhancing the performance of electronic devices.

6.3 Consumer Goods

From kitchen appliances to hardware tools, zinc die casting is employed in various consumer goods, providing durability and aesthetic appeal. The ability to create complex shapes allows designers to innovate freely, enhancing product functionality and design.

7. Future Trends in Zinc Die Casting

The future of zinc die casting is poised for exciting developments as technology continues to evolve.

7.1 Smart Manufacturing

The rise of smart manufacturing, characterized by interconnected systems and data analytics, promises to enhance the efficiency of zinc die casting processes. Predictive maintenance, data-driven decision-making, and real-time performance monitoring will further optimize production.

7.2 Customization and On-Demand Production

As consumer preferences shift towards personalized products, zinc die casting will adapt to enable customization and on-demand production, allowing manufacturers to respond swiftly to market demands.

8. FAQs About Zinc Die Casting

8.1 What materials are typically used in zinc die casting?

Zinc die casting primarily uses zinc alloys, with the most common being ZA-8, ZA-12, and ZA-27, each offering unique properties suited for different applications.

8.2 How does zinc die casting compare to aluminum die casting?

While both processes offer high precision, zinc die casting is generally more cost-effective for smaller parts and provides superior surface finishes compared to aluminum die casting.

8.3 What are the typical cycle times for zinc die casting?

Cycle times can vary based on part complexity and size but typically range from 15 to 60 seconds for production runs.

8.4 Can zinc die casting be used for high-volume production?

Yes, zinc die casting is highly suited for high-volume production due to its rapid cycle times and efficiency in material usage.

8.5 Is zinc die casting environmentally friendly?

Yes, zinc is highly recyclable and the die casting process generates minimal waste, making it an environmentally friendly manufacturing option.

9. Conclusion: The Future of Zinc Die Casting

The advancements in zinc die casting reflect a significant shift towards more efficient, sustainable, and precise manufacturing processes. As industries continue to seek innovative solutions to meet rising demand and environmental challenges, zinc die casting stands out as a versatile and effective technology. By embracing automation, smart manufacturing, and enhanced materials, the future of zinc die casting is bright, promising to redefine efficiency in molding and beyond.

zinc die casting

28

2025-10

Elevating Quality Standards: The Role of Aluminum Casting in Mechanical Processing

25

2025-10

22

2025-10

Efficiency Redefined: Advancements in Zinc Die Casting for Molding

19

2025-10

Understanding Die Casting Machines: An Essential Guide for Metalworking Professionals

16

2025-10

Unleashing the Potential of Aluminum Die Casting in Modern Manufacturing

13

2025-10

Understanding Aluminum Alloy Molds: A Key Component in Precision Manufacturing

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695