28

2025

-

10

Elevating Quality Standards: The Role of Aluminum Casting in Mechanical Processing

Author:

Elevating Quality Standards: The Role of Aluminum Casting in Mechanical Processing

Table of Contents

- Introduction to Aluminum Casting in Mechanical Processing

- Understanding Aluminum Casting: A Fundamental Overview

- Benefits of Aluminum Casting in Manufacturing

- Key Applications of Aluminum Casting in Mechanical Processing

- How Aluminum Casting Elevates Quality Standards

- Future Trends in Aluminum Casting and Mechanical Processing

- Challenges and Considerations in Aluminum Casting

- Conclusion: The Future of Mechanical Processing with Aluminum Casting

- FAQs about Aluminum Casting in Mechanical Processing

Introduction to Aluminum Casting in Mechanical Processing

The landscape of mechanical processing has undergone significant changes in recent years, driven largely by advancements in materials and manufacturing techniques. Among these innovations, **aluminum casting** has emerged as a pivotal method for producing high-quality components. This article delves deep into the role of aluminum casting in mechanical processing, examining its benefits, applications, and how it contributes to raising quality standards across industries.

Understanding Aluminum Casting: A Fundamental Overview

Aluminum casting involves pouring molten aluminum into a mold to create various shapes and components. This method is favored for its versatility, lightweight properties, and resistance to corrosion. **Mechanical processing** often requires components that are not just functional but also reliable and durable. Aluminum casting meets these demands through various techniques, including sand casting, die casting, and investment casting. Each method has its unique advantages, suited for different applications and production volumes.

Types of Aluminum Casting Techniques

Sand Casting

Sand casting is one of the oldest and most widely used casting methods. It involves creating a mold from sand and then pouring molten aluminum into it. This technique is ideal for producing large components with intricate designs and is often used in low to medium production volumes.

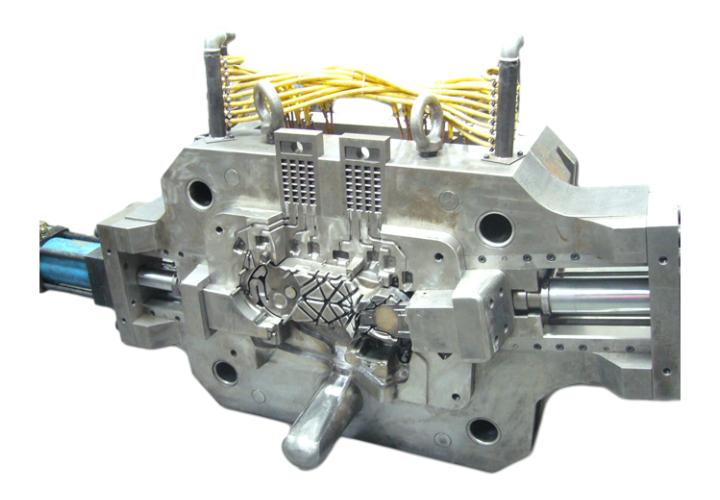

Die Casting

Die casting is a pressure casting method that produces high-volume parts with excellent surface finish and dimensional accuracy. It is suitable for manufacturing small to medium-sized components and is often employed in the automotive and consumer goods industries.

Investment Casting

Investment casting, also known as lost-wax casting, is a precision casting method that allows for complex geometries and fine detail. This technique is often used in industries that demand high-quality components, such as aerospace and medical devices.

Benefits of Aluminum Casting in Manufacturing

The adoption of aluminum casting in mechanical processing offers numerous benefits that contribute to improving overall manufacturing quality.

Lightweight and Durable

Aluminum is significantly lighter than other metals, making it a preferred choice for applications where weight reduction is critical, such as in automotive and aerospace industries. Despite its lightweight nature, aluminum is also highly durable and can withstand various environmental conditions.

Corrosion Resistance

Aluminum inherently possesses excellent corrosion resistance due to the formation of a protective oxide layer. This characteristic enhances the longevity of components used in harsh environments, reducing maintenance costs and improving overall quality.

Enhanced Production Efficiency

Aluminum casting methods, particularly die casting, allow for high-speed production and reduced cycle times. This efficiency translates to lower manufacturing costs and improved output, positively impacting quality standards.

Versatility in Design

The versatility of aluminum casting enables manufacturers to produce complex shapes and intricate designs. This flexibility allows for innovation in product development, meeting the evolving demands of various industries.

Key Applications of Aluminum Casting in Mechanical Processing

Aluminum casting finds applications across a diverse range of industries, each benefiting from its unique properties.

Aerospace Industry

In the aerospace industry, weight reduction is paramount. Aluminum components are extensively used in aircraft structures, engines, and various systems to enhance performance and fuel efficiency.

Automotive Sector

The automotive sector utilizes aluminum casting for engine blocks, transmission cases, and wheels. The lightweight characteristics of aluminum contribute to improved fuel economy and reduced emissions.

Consumer Goods

From kitchen appliances to electronic devices, aluminum casting is widely used in consumer goods manufacturing. Its aesthetic appeal and functionality make it a popular choice for various products.

Industrial Equipment

Industrial machinery and equipment often utilize aluminum castings for components such as housings, brackets, and frames. The strength and durability of aluminum ensure reliability in demanding applications.

How Aluminum Casting Elevates Quality Standards

The integration of aluminum casting into mechanical processing has a direct impact on quality standards.

Precision and Accuracy

Advanced casting techniques provide high precision and dimensional accuracy, ensuring that components fit perfectly in their assemblies. This accuracy is vital for maintaining the functionality and safety of mechanical systems.

Consistency in Production

Aluminum casting enables manufacturers to achieve consistency in production quality. Automated processes, particularly in die casting, help minimize variations and defects, enhancing the reliability of products.

Meeting Regulatory Standards

Manufacturers using aluminum casting can meet stringent regulatory standards required in many industries, including aerospace and automotive. This compliance not only enhances product quality but also builds trust with customers.

Improved Surface Finish

Modern aluminum casting techniques result in superior surface finishes, reducing the need for extensive post-processing. This contributes to overall quality and reduces production times, further elevating industry standards.

Future Trends in Aluminum Casting and Mechanical Processing

As technology continues to evolve, so do the trends in aluminum casting.

Increased Automation

The future of aluminum casting will see increased automation in production lines. Robotics and AI-driven systems will enhance efficiency and accuracy, further improving quality standards in mechanical processing.

3D Printing in Aluminum Casting

The incorporation of 3D printing technology in aluminum casting is gaining traction. This innovative approach allows for rapid prototyping and the ability to create complex geometries that traditional methods may struggle with.

Sustainability Initiatives

Sustainability is becoming a key focus in manufacturing, and aluminum casting is no exception. Efforts to recycle aluminum and reduce waste will play a significant role in future casting practices, enhancing both environmental performance and product quality.

Advanced Alloys

The development of advanced aluminum alloys will lead to improved properties such as higher strength, better corrosion resistance, and thermal conductivity. These new materials will open up further possibilities for high-quality applications.

Challenges and Considerations in Aluminum Casting

While aluminum casting offers many benefits, it also presents certain challenges that manufacturers need to address.

Cost of Equipment

The initial investment in advanced casting equipment can be high. However, the long-term benefits often justify this cost through increased efficiency and quality.

Skill Requirements

The complexity of modern aluminum casting techniques requires skilled personnel. Ensuring a workforce that is knowledgeable and experienced in these practices is essential for maintaining quality standards.

Material Quality Control

Maintaining the quality of aluminum alloys is crucial. Variations in material composition can lead to defects and inconsistencies in the final products, requiring robust quality control measures.

Conclusion: The Future of Mechanical Processing with Aluminum Casting

Aluminum casting is revolutionizing mechanical processing by elevating quality standards across various industries. Its lightweight, durable, and corrosion-resistant properties make it an ideal choice for a multitude of applications. As we look to the future, advancements in automation, technology, and sustainability will further enhance the role of aluminum casting in manufacturing. Embracing these innovations will not only improve production efficiency but also lead to the creation of superior quality components that meet the increasing demands of a competitive market.

FAQs about Aluminum Casting in Mechanical Processing

1. What is aluminum casting used for?

Aluminum casting is used for producing a variety of components across numerous industries, including aerospace, automotive, consumer goods, and industrial equipment.

2. How does aluminum casting improve product quality?

Aluminum casting enhances product quality through precision manufacturing, consistency in production, and the ability to meet regulatory standards.

3. What are the different methods of aluminum casting?

The main methods of aluminum casting include sand casting, die casting, and investment casting, each suited for different applications and production needs.

4. Is aluminum casting environmentally friendly?

Aluminum casting can be environmentally friendly, particularly when recycling practices are in place, reducing waste and energy consumption during production.

5. What are the challenges faced in aluminum casting?

Challenges in aluminum casting include high initial equipment costs, the need for skilled labor, and the importance of maintaining material quality.

By understanding the multifaceted advantages of aluminum casting and its role in elevating quality standards, manufacturers can harness its potential to improve their mechanical processing capabilities.

custom aluminum casting

28

2025-10

Elevating Quality Standards: The Role of Aluminum Casting in Mechanical Processing

25

2025-10

22

2025-10

Efficiency Redefined: Advancements in Zinc Die Casting for Molding

19

2025-10

Understanding Die Casting Machines: An Essential Guide for Metalworking Professionals

16

2025-10

Unleashing the Potential of Aluminum Die Casting in Modern Manufacturing

13

2025-10

Understanding Aluminum Alloy Molds: A Key Component in Precision Manufacturing

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695