19

2025

-

10

Understanding Die Casting Machines: An Essential Guide for Metalworking Professionals

Author:

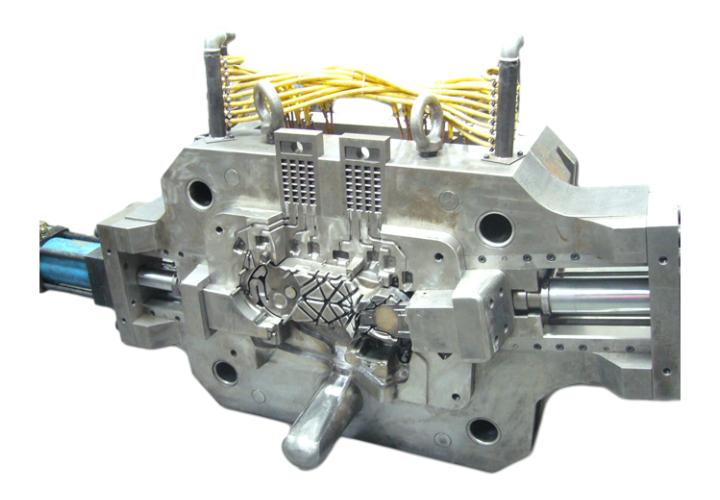

The operation of a die casting machine involves a series of well-coordinated steps that include melting the metal, injecting it into a mold, and allowing it to cool and solidify. This methodology enables the efficient production of complex geometries that are often difficult to achieve with traditional manufacturing techniques. The molds, or dies, used in the process are crafted from durable materials to withstand the high pressures involved, ensuring longevity and reliability.

One of the primary advantages of using die casting machines is their ability to produce large quantities of components with minimal variation. This consistency is vital for industries where precision is crucial, such as automotive, aerospace, and electronics. Furthermore, the die casting process reduces the need for extensive machining post-casting, thereby enhancing production efficiency and lowering material waste.

In addition to efficiency, die casting machines offer significant benefits in terms of surface finish and detail. The rapid cooling of the molten metal within the mold results in a smooth surface and refined detail, often eliminating the need for secondary finishing processes. This characteristic not only speeds up production times but also helps in reducing costs associated with additional treatments.

Die casting technology has seen several advancements, including the development of automated systems that enhance precision and reduce human intervention. Modern die casting machines are equipped with advanced controls and monitoring systems that optimize the process parameters, ensuring consistent output quality. These innovations are essential for maintaining competitiveness in the fast-paced metalworking industry.

Moreover, as environmental concerns continue to grow, die casting machines are evolving to incorporate more sustainable practices. Many manufacturers are exploring eco-friendly metals and recycling methods to minimize their environmental footprint. These advancements not only benefit the planet but can also appeal to a growing market of environmentally conscious consumers.

In summary, die casting machines represent a cornerstone technology in the metalworking sector, combining efficiency, precision, and innovation. Understanding their operation and applications is crucial for professionals in the industry who aim to enhance their manufacturing processes and meet the increasingly complex demands of the market. By leveraging die casting technology, manufacturers can achieve operational excellence while producing high-quality components that stand the test of time.

die casting machine

28

2025-10

Elevating Quality Standards: The Role of Aluminum Casting in Mechanical Processing

25

2025-10

22

2025-10

Efficiency Redefined: Advancements in Zinc Die Casting for Molding

19

2025-10

Understanding Die Casting Machines: An Essential Guide for Metalworking Professionals

16

2025-10

Unleashing the Potential of Aluminum Die Casting in Modern Manufacturing

13

2025-10

Understanding Aluminum Alloy Molds: A Key Component in Precision Manufacturing

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695