20

2025

-

08

Aluminum Die Casting: Precision, Strength, and Innovation in Metal Forming

Author:

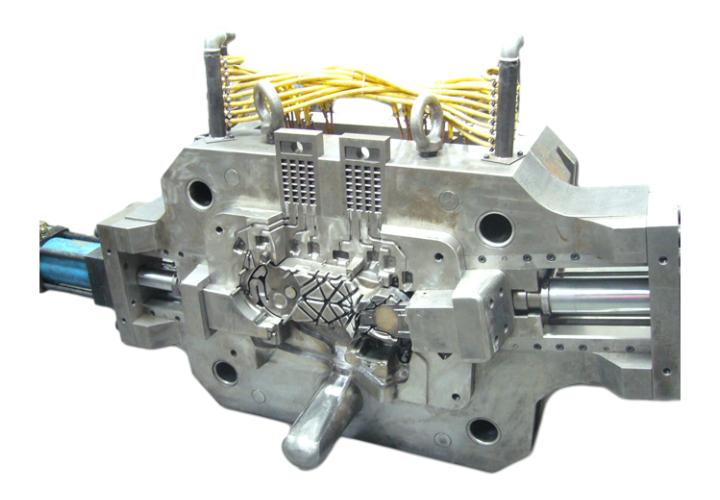

Aluminum die casting is one of the most efficient, versatile, and widely used metal-forming processes in modern manufacturing, combining high precision with remarkable strength and lightweight performance. By injecting molten aluminum under high pressure into steel molds, also called dies, this process creates complex and durable components that are integral to countless industries. From automotive and aerospace to electronics, consumer goods, and industrial machinery, aluminum die casting has revolutionized how manufacturers achieve both functionality and cost efficiency.

One of the greatest advantages of aluminum die casting lies in its ability to produce intricate shapes with tight tolerances, which would be extremely difficult or uneconomical to achieve using other manufacturing methods. This makes it possible to design lightweight yet structurally strong components that reduce material usage and enhance performance. For example, in the automotive sector, aluminum die-cast parts such as engine blocks, transmission housings, and structural components contribute to reducing vehicle weight, improving fuel efficiency, and enhancing overall durability.

Another defining feature of aluminum die casting is its superior surface finish. Parts come out of the die with smooth surfaces that often require minimal machining or finishing, saving time and costs. Additionally, aluminum’s natural resistance to corrosion further increases the lifespan of die-cast parts, making them suitable even for harsh environments such as marine or industrial applications.

The process itself offers rapid production cycles, allowing for mass production of identical parts with consistent quality. Modern advancements, such as vacuum-assisted die casting and computer-controlled systems, further improve accuracy, reduce porosity, and enable more complex geometries. This makes the process ideal for high-volume industries that demand precision and efficiency without compromising quality.

Sustainability also plays a key role. Aluminum is highly recyclable without losing its inherent properties, and die casting efficiently utilizes scrap material, making it an eco-friendly solution that aligns with today’s focus on reducing environmental impact.

In essence, aluminum die casting stands at the crossroads of innovation, performance, and sustainability. It is not just a method of shaping metal — it is a driving force behind modern design and engineering, enabling industries to achieve breakthroughs in efficiency, strength, and reliability.

28

2025-10

Elevating Quality Standards: The Role of Aluminum Casting in Mechanical Processing

25

2025-10

22

2025-10

Efficiency Redefined: Advancements in Zinc Die Casting for Molding

19

2025-10

Understanding Die Casting Machines: An Essential Guide for Metalworking Professionals

16

2025-10

Unleashing the Potential of Aluminum Die Casting in Modern Manufacturing

13

2025-10

Understanding Aluminum Alloy Molds: A Key Component in Precision Manufacturing

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695