03

2025

-

11

Aluminum Prototype Casting: A Comprehensive Guide to Precision Engineering

Author:

Aluminum Prototype Casting: A Step Towards Precision Engineering

Introduction: The Importance of Aluminum Prototype Casting in Precision Engineering

In the ever-evolving landscape of manufacturing, **aluminum prototype casting** plays a crucial role in enhancing precision engineering. This process not only allows for the rapid production of complex designs but also significantly reduces the time and cost associated with traditional manufacturing methods. **Prototype casting** is particularly beneficial in industries like automotive, aerospace, and electronics, where precision and efficiency are paramount.

Table of Contents

- What is Aluminum Prototype Casting?

- Benefits of Aluminum Prototype Casting

- Techniques in Aluminum Prototype Casting

- The Casting Process: Step-by-Step

- Materials Used in Aluminum Prototype Casting

- Applications of Aluminum Prototype Casting

- Quality Control in Aluminum Casting

- Future Trends in Aluminum Prototype Casting

- FAQs

- Conclusion

What is Aluminum Prototype Casting?

Aluminum prototype casting is a manufacturing process that involves creating **aluminum prototypes** using various casting techniques. This method allows designers and engineers to fabricate parts from aluminum alloys, which are lightweight yet strong, making them ideal for prototypes. The precision of casting helps in achieving intricate designs and fine tolerances, key aspects for prototypes intended for testing and evaluation.

Benefits of Aluminum Prototype Casting

Aluminum prototype casting offers a multitude of advantages:

1. Rapid Prototyping

One of the primary benefits of aluminum prototype casting is its ability to produce parts quickly. This speed enables engineers to iterate designs faster, allowing for quick modifications based on testing feedback.

2. Cost Efficiency

Aluminum casting reduces the need for expensive tooling and setup processes, which significantly lowers production costs. Manufacturers can produce small batches economically, making it ideal for prototypes.

3. High Precision and Accuracy

The casting process can achieve tight tolerances and complex geometries that would be challenging to fabricate with traditional machining methods. This precision is vital in industries where every millimeter matters.

4. Lightweight and Durable Parts

Aluminum is renowned for its lightweight properties combined with strength and corrosion resistance. This makes it an ideal material for components that require durability without adding significant weight.

5. Versatility in Design

Aluminum prototype casting allows for a wide range of design possibilities. Whether it’s intricate shapes or large components, aluminum can be molded to meet diverse engineering needs.

Techniques in Aluminum Prototype Casting

Various techniques are employed in aluminum prototype casting, each with its unique benefits:

1. Sand Casting

Sand casting is one of the oldest methods and remains popular due to its flexibility and low cost. In this technique, a sand mold is created around a pattern, and molten aluminum is poured into the mold to form the desired shape.

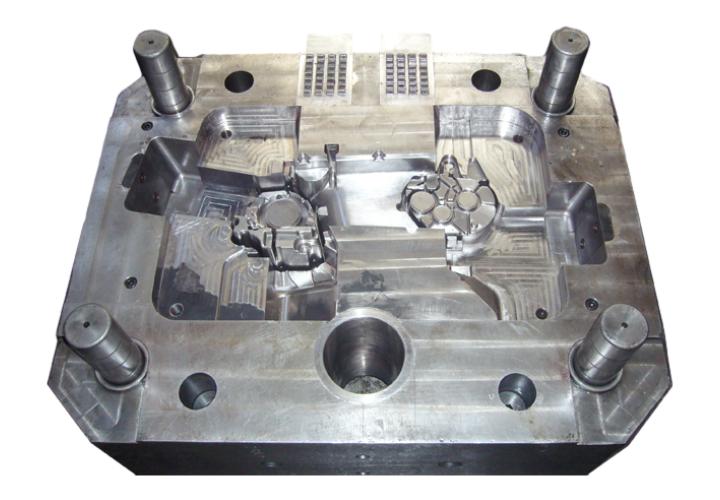

2. Die Casting

Die casting involves forcing molten aluminum into a steel mold under high pressure. This method is ideal for producing large quantities of parts with a high level of precision. It is commonly used for automotive and electronic components.

3. Investment Casting

Investment casting, or lost-wax casting, provides an exceptional level of detail and surface finish. It is particularly useful for complex geometries and is often employed in aerospace applications.

4. Permanent Mold Casting

In permanent mold casting, a reusable mold is used to produce parts. This method allows for better dimensional control and surface finish compared to sand casting, making it suitable for production runs.

The Casting Process: Step-by-Step

Understanding the casting process is vital for optimizing production. Here’s a step-by-step breakdown:

Step 1: Design and Pattern Creation

The process begins with designing the part using CAD software. A physical pattern is then created, typically from wood or metal, which will form the mold.

Step 2: Mold Preparation

The chosen method for casting determines how the mold is created. For sand casting, sand is mixed with a binder and packed around the pattern to form the mold.

Step 3: Melting Aluminum

Aluminum is melted in a furnace, reaching temperatures around 660°C (1220°F). This molten aluminum is then ready to be poured into the mold.

Step 4: Pouring the Molten Aluminum

Once the aluminum is molten, it is poured into the prepared mold. Care must be taken to avoid defects such as air pockets or inclusions.

Step 5: Cooling and Solidification

After pouring, the aluminum is allowed to cool and solidify within the mold. Cooling times vary based on the size and thickness of the part.

Step 6: Mold Removal and Finishing

Once solidified, the mold is removed, and the part is subjected to finishing processes, such as machining or surface treatment, to achieve the desired specifications.

Materials Used in Aluminum Prototype Casting

Choosing the right materials is critical in aluminum prototype casting:

1. Aluminum Alloys

Different aluminum alloys provide varying properties. Common alloys used include 356.0 (A356) and 6061, each offering specific mechanical properties suitable for different applications.

2. Molding Materials

The choice of mold material affects the casting quality. Sand molds are commonly used for their flexibility, while metal molds are preferred for their durability and ability to produce higher precision parts.

3. Additives and Coatings

Additives may be used to improve fluidity and reduce defects in the casting process. Coatings can also be applied to molds to enhance surface finish and ease part removal.

Applications of Aluminum Prototype Casting

Aluminum prototype casting is utilized across various industries:

1. Automotive Industry

In the automotive sector, aluminum components are cast for engine blocks, transmission cases, and structural parts, reducing overall vehicle weight and improving fuel efficiency.

2. Aerospace Industry

Aerospace components demand high precision and lightweight materials, making aluminum casting ideal for parts such as brackets, housings, and structural frameworks.

3. Electronics Manufacturing

In electronics, aluminum prototypes are used for heat sinks, enclosures, and mechanical supports, benefiting from aluminum's thermal conductivity and lightweight characteristics.

4. Consumer Products

From kitchen appliances to sporting goods, aluminum prototype casting enables the production of durable, lightweight consumer products that meet modern design standards.

Quality Control in Aluminum Casting

Ensuring quality in aluminum prototype casting is essential to meet industry standards:

1. Inspection Methods

Visual inspections, dimensional checks, and non-destructive testing (NDT) methods help identify defects in cast parts.

2. Process Optimization

Implementing statistical process control (SPC) can help monitor and optimize the casting process, ensuring consistent quality in production.

3. Certification and Standards

Adhering to industry standards such as ISO and ASTM can enhance product reliability and customer trust.

Future Trends in Aluminum Prototype Casting

As technology advances, the future of aluminum prototype casting looks promising:

1. Automation and Robotics

Increased automation in casting processes can lead to higher efficiency and reduced labor costs, paving the way for more streamlined production.

2. Advanced Materials

Research into new aluminum alloys and composites is expected to enhance performance characteristics, expanding their application in demanding environments.

3. Sustainable Practices

With a growing focus on sustainability, aluminum recycling and eco-friendly casting methods are becoming more prevalent, reducing environmental impact.

FAQs

1. What is the main advantage of aluminum prototype casting?

The main advantage is the ability to produce complex shapes with high precision quickly and cost-effectively.

2. How does aluminum compare to other materials for prototyping?

Aluminum is lighter and more durable than many materials, offering excellent thermal properties and resistance to corrosion.

3. What industries benefit most from aluminum prototype casting?

The automotive, aerospace, electronics, and consumer goods industries are among the top beneficiaries.

4. Can aluminum prototypes be machined after casting?

Yes, many aluminum prototypes undergo machining or finishing processes to achieve tighter tolerances or specific surface finishes.

5. What are the common defects in aluminum casting?

Common defects include porosity, shrinkage, and inclusions, which can affect the strength and appearance of the final product.

Conclusion

Aluminum prototype casting represents a significant advancement in precision engineering, enabling manufacturers to produce high-quality prototypes rapidly and cost-effectively. By understanding the intricacies of the casting process, selecting the right materials, and implementing stringent quality controls, businesses can leverage this technology to enhance their product offerings. As the industry continues to evolve, staying abreast of trends and innovations in aluminum casting will be essential for maintaining a competitive edge.

prototype aluminum casting

Previous Page

Previous Page

31

2025-10

Understanding Die Casting Molds: Key Insights for Professionals in the Manufacturing Industry

28

2025-10

Elevating Quality Standards: The Role of Aluminum Casting in Mechanical Processing

25

2025-10

22

2025-10

Efficiency Redefined: Advancements in Zinc Die Casting for Molding

19

2025-10

Understanding Die Casting Machines: An Essential Guide for Metalworking Professionals

16

2025-10

Unleashing the Potential of Aluminum Die Casting in Modern Manufacturing

13

2025-10

Understanding Aluminum Alloy Molds: A Key Component in Precision Manufacturing

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695