18

2025

-

08

Alloy Manufacturing: Crafting the Backbone of Modern Industry

Author:

Alloy manufacturing stands at the core of modern industrial innovation, providing materials that combine strength, durability, and functionality to meet the ever-increasing demands of technology-driven sectors. Alloys, which are mixtures of two or more metallic elements, are engineered to enhance specific mechanical, chemical, and thermal properties that pure metals alone cannot achieve. The process of alloy manufacturing involves precise selection of raw materials, controlled melting and blending, and meticulous casting, forging, or rolling operations to ensure uniform composition, microstructure, and performance consistency.

The choice of alloy composition is dictated by its intended application. For instance, steel alloys incorporating elements such as chromium, nickel, and molybdenum offer exceptional hardness, corrosion resistance, and high-temperature performance, making them ideal for automotive, construction, and aerospace applications. Aluminum alloys, often combined with copper, magnesium, or zinc, provide a lightweight yet strong alternative suitable for transportation, aerospace, and electronics, where weight reduction and energy efficiency are critical. Copper-based alloys, including bronze and brass, are valued for their excellent conductivity, corrosion resistance, and machinability, making them indispensable in electrical components, plumbing, and decorative applications.

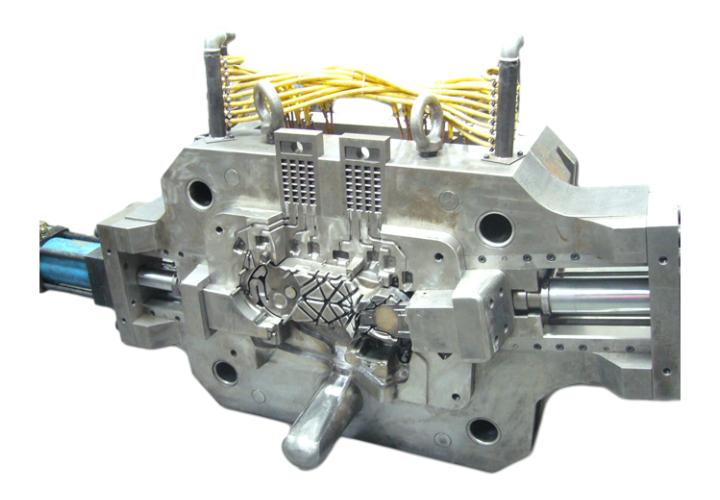

Advanced alloy manufacturing processes employ a combination of metallurgical science and precision engineering. The melting stage requires careful temperature control and the use of inert or protective atmospheres to prevent oxidation and contamination. Subsequent casting or solidification processes determine the grain structure, mechanical properties, and surface quality of the final product. Techniques such as vacuum induction melting, continuous casting, and powder metallurgy are employed for specialty alloys, allowing manufacturers to produce complex shapes, ultra-high-performance materials, or components with tailored microstructures.

Modern alloy manufacturing emphasizes both performance and sustainability. Recyclable metals are increasingly used to reduce resource consumption and environmental impact. Efficient energy usage in furnaces and melting operations, along with automated process controls, ensures minimal material waste and consistent quality. Additionally, surface treatments, heat treatments, and finishing processes can further enhance corrosion resistance, wear resistance, and fatigue life, extending the lifespan of critical components and reducing the total cost of ownership.

Alloy manufacturing also plays a vital role in innovation across emerging industries. In aerospace, lightweight titanium and aluminum alloys improve fuel efficiency and structural performance. In electronics, advanced conductive alloys enable faster, more reliable circuits. In renewable energy, corrosion-resistant and high-strength alloys are essential for wind turbines, solar panels, and energy storage systems. The ability to design alloys with precise properties tailored to specific applications underscores their importance as foundational materials in technological advancement.

In conclusion, alloy manufacturing represents the seamless integration of material science, engineering precision, and industrial innovation. By producing metals with enhanced mechanical, chemical, and thermal properties, manufacturers deliver components that drive efficiency, reliability, and sustainability across countless industries. From automotive and aerospace to electronics and renewable energy, alloys are indispensable to modern engineering, providing the strength, resilience, and versatility required to meet the evolving demands of the global economy.

28

2025-10

Elevating Quality Standards: The Role of Aluminum Casting in Mechanical Processing

25

2025-10

22

2025-10

Efficiency Redefined: Advancements in Zinc Die Casting for Molding

19

2025-10

Understanding Die Casting Machines: An Essential Guide for Metalworking Professionals

16

2025-10

Unleashing the Potential of Aluminum Die Casting in Modern Manufacturing

13

2025-10

Understanding Aluminum Alloy Molds: A Key Component in Precision Manufacturing

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695