07

2025

-

02

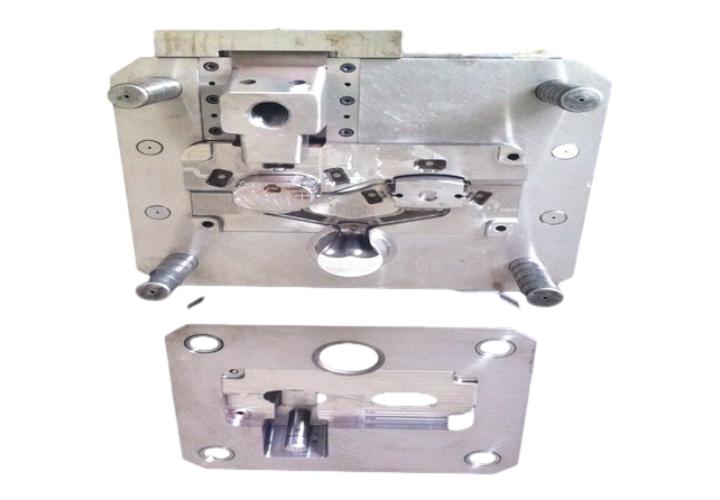

The role of china Zinc Die Casting in home appliance manufacturing

Author:

1. Providing diverse component shapes and functions

In home appliances, many components require complex and precise shapes. The Zinc Die Casting process can produce components of various shapes, from knobs with fine textures to complex shells. For example, the air outlet grille of the air conditioner can be precisely shaped by Zinc Die Casting, which can ensure both beauty and functional requirements of air circulation. The same is true for the base of the TV. Zinc Die Casting can achieve a unique design while ensuring sufficient stability to support the weight of the TV.

2. Ensure good mechanical properties

Zinc Die Casting components have good strength and hardness, which can meet various mechanical requirements of home appliances in daily use. For example, some transmission parts inside the washing machine, the parts manufactured by Zinc Die Casting can withstand repeated rotation and friction driven by the motor, and are not easy to deform or damage. Moreover, Zinc Die Casting components can also have a certain degree of shock resistance under reasonable design, such as some supporting structures around the refrigerator compressor, which can still maintain the stability of the overall structure when the compressor vibrates when working.

3. It helps to improve the appearance quality

Zinc Die Casting products have a smooth surface, and their beauty can be further improved through various surface treatment processes. This is very important for home appliances that pursue exquisite appearance. For example, the shell of some high-end ovens, after Zinc Die Casting and subsequent electroplating, spraying and other surface treatments, presents a bright and uniform appearance, which improves the overall grade of the product. It is also easy to clean and meets the needs of home use scenarios.

4. It is conducive to large-scale production

The Zinc Die Casting process is suitable for large-scale batch production, which is very critical for industries such as home appliances that require mass production of the same parts. It can produce a large number of standard parts in a short time, and can effectively control production costs through mold optimization and other means, thereby meeting the production efficiency and cost control requirements of home appliance manufacturers.

Zinc Die Casting

Previous Page

Previous Page

09

2025-12

Innovative Designs Made Possible: The Influence of Die Casting Machines

06

2025-12

Understanding Aluminum Die Casting: A Comprehensive Guide for Manufacturers

03

2025-12

The Future of Machining: Innovations in Aluminum Alloy Mold Advancements

30

2025-11

The Advantages and Applications of Zinc Alloy Molds in Manufacturing

27

2025-11

Exploring the Versatility of Zinc Alloy in Modern Applications

24

2025-11

Exploring the Versatility and Applications of Aluminum Alloys

21

2025-11

Revolutionizing the World of Molding: The Advantages of Aluminum Casting

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695