09

2024

-

01

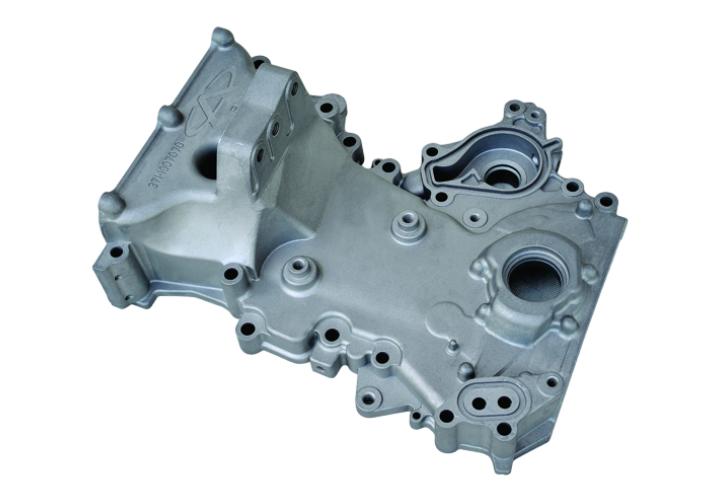

car companies to produce integrated die-casting models

Author:

From the perspective of business model, there are two main ways for car companies to produce integrated die-casting models: one is the self-developed mode of the Oems: the Oems directly purchase die-casting machines, molds and materials and other materials, and build their own factories to produce die-casting parts. This model is represented by Tesla, Xiaopeng and Volvo. The other is the procurement mode: the Oems directly purchase the die-casting parts from the die-casting manufacturers, and the relevant materials are purchased by the die-casting manufacturers, and the die-casting parts are delivered to the oems after production. This model is represented by Gaohe, Weilai and ideal. In the long run, the future automotive integration die casting will gradually return to the procurement mode. On the one hand, the self-built production line of the Oems is under great financial pressure, and the operation management in the later stage is very energy consuming. Tesla, the representative of the self-developed model, has begun to cooperate with die casting manufacturers, and plans to solve the future new production capacity by external procurement. The main purpose of self-research is to master integrated die casting knowhow, so as to facilitate technical communication with suppliers in the future.

die-casting models

Previous Page

Previous Page

03

2025-11

Aluminum Prototype Casting: A Comprehensive Guide to Precision Engineering

31

2025-10

Understanding Die Casting Molds: Key Insights for Professionals in the Manufacturing Industry

28

2025-10

Elevating Quality Standards: The Role of Aluminum Casting in Mechanical Processing

25

2025-10

22

2025-10

Efficiency Redefined: Advancements in Zinc Die Casting for Molding

19

2025-10

Understanding Die Casting Machines: An Essential Guide for Metalworking Professionals

16

2025-10

Unleashing the Potential of Aluminum Die Casting in Modern Manufacturing

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695