09

2024

-

01

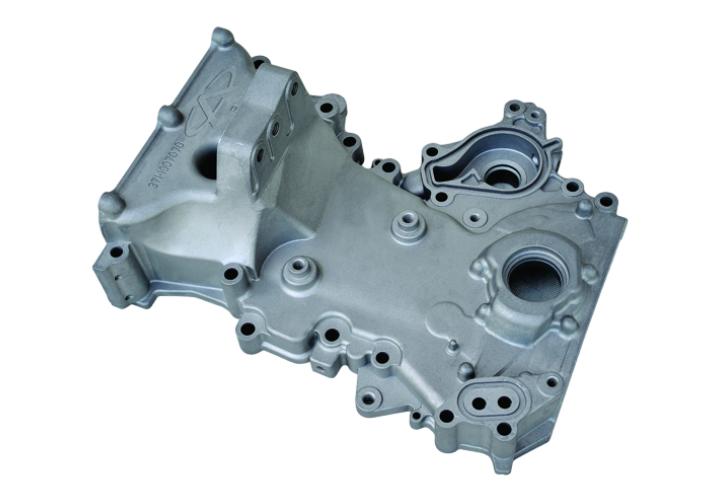

Tesla opens a new chapter of integrated die casting

Author:

Tesla opens a new chapter of integrated die casting. The essence of integrated die casting is to achieve a major breakthrough in the size of parts and application parts of aluminum alloy high die casting technology, refers to the use of large tonnage die casting machine, a number of separate, dispersed parts are highly integrated, die-casting molding into several large aluminum castings, so as to replace a number of parts first stamping and welding or riveting combination. In September 2020, Musk announced for the first time that the integrated die-casting technology would be used to produce the rear body floor of the Model Y, and would gradually replace more than 370 structural parts of the entire body floor with 2-3 large die-casting parts, opening a new chapter in the integration of aluminum alloy die-casting for large automotive components.

integrated die casting

Previous Page

03

2025-11

Aluminum Prototype Casting: A Comprehensive Guide to Precision Engineering

31

2025-10

Understanding Die Casting Molds: Key Insights for Professionals in the Manufacturing Industry

28

2025-10

Elevating Quality Standards: The Role of Aluminum Casting in Mechanical Processing

25

2025-10

22

2025-10

Efficiency Redefined: Advancements in Zinc Die Casting for Molding

19

2025-10

Understanding Die Casting Machines: An Essential Guide for Metalworking Professionals

16

2025-10

Unleashing the Potential of Aluminum Die Casting in Modern Manufacturing

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695