09

2024

-

01

Aisin Japan will use integrated die casting technology

Author:

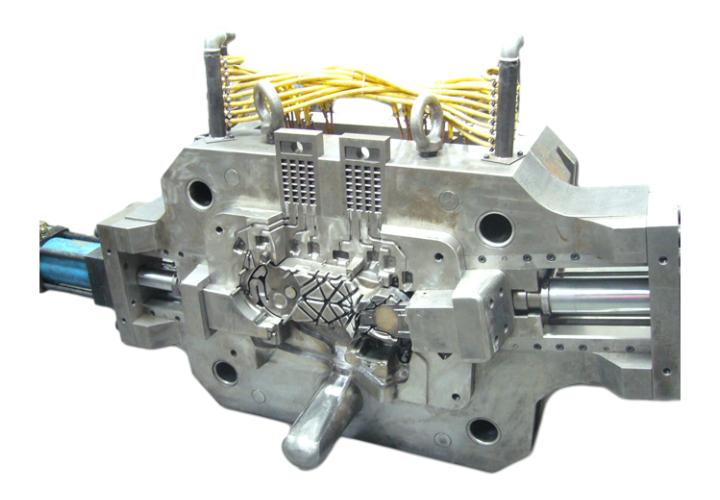

Japanese auto parts supplier Aisin said on September 14 that it will use integrated die-casting (Gigacast) technology to produce aluminum components for electric vehicles, aiming to simplify production processes and reduce costs.

In 2021, the former Japanese Aisin Precision Machinery Co., LTD and Aisin AW Co., Ltd. were merged into Aisin (Aisin Group Corporation). Aisin Group has 207 subsidiaries. In China, Aisin Group has dozens of subsidiaries (including joint ventures), including Foshan in Guangdong Province, Tangshan in Hebei Province, Taizhou in Zhejiang Province and other places. The main production engine, transmission, cylinder head and other aluminum die-casting based auto parts.

Some analysis pointed out that the integrated die casting technology, not only new energy vehicles, is the entire automobile industry chain can be used, and even with the promotion of technology, the future is not only the car, but also may develop in the direction of other buses, trucks, etc., which is undoubtedly once again to the concept of integrated die casting to convey a positive signal.

integrated die casting technology

28

2025-10

Elevating Quality Standards: The Role of Aluminum Casting in Mechanical Processing

25

2025-10

22

2025-10

Efficiency Redefined: Advancements in Zinc Die Casting for Molding

19

2025-10

Understanding Die Casting Machines: An Essential Guide for Metalworking Professionals

16

2025-10

Unleashing the Potential of Aluminum Die Casting in Modern Manufacturing

13

2025-10

Understanding Aluminum Alloy Molds: A Key Component in Precision Manufacturing

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695