09

2024

-

01

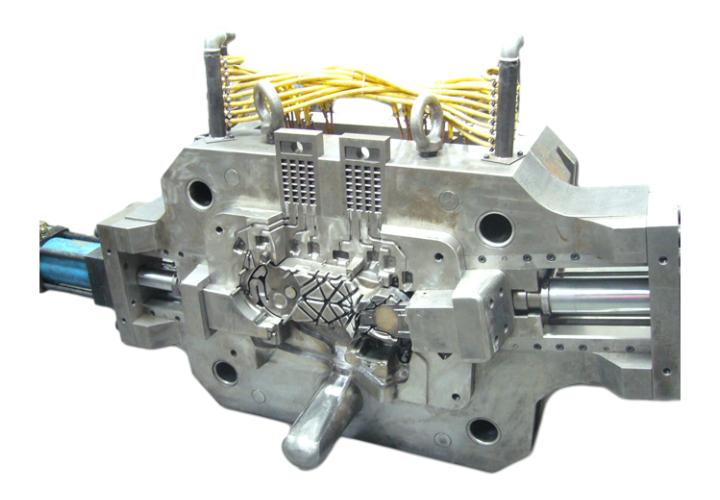

The polar Krypton car has a mid-piece die-cast dragonfly construction

Author:

Recently (September 15), polar Krypton safety camp activities were held in Ningbo Hangzhou Bay, which is the first time polar Krypton from the structure safety, three power safety, manufacturing safety and other aspects of the system to reveal the polar Krypton safety system. At the event, polar Krypton officially announced the latest evolution of integrated die casting: the world's first middle part of the integrated die casting dragonfly structure, the middle part of the integrated die casting dragonfly structure will be mass-produced on polar Krypton 001 FR.

According to reports, polar Krypton the world's first midsection integral die-cast dragonfly structure, its unique structural design, reduce 16 parts, reduce the connection point 66 points, achieve 7% weight reduction, seat installation point stiffness increased by an average of 18%, so that the body lighter, stronger, more comfortable to ride.

die-cast dragonfly construction

Previous Page

28

2025-10

Elevating Quality Standards: The Role of Aluminum Casting in Mechanical Processing

25

2025-10

22

2025-10

Efficiency Redefined: Advancements in Zinc Die Casting for Molding

19

2025-10

Understanding Die Casting Machines: An Essential Guide for Metalworking Professionals

16

2025-10

Unleashing the Potential of Aluminum Die Casting in Modern Manufacturing

13

2025-10

Understanding Aluminum Alloy Molds: A Key Component in Precision Manufacturing

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695