09

2024

-

01

Caster Aluminum (Chongqing) integrated molding new energy vehicle parts project started

Author:

Wansheng Daily reported that a few days ago, the first phase of the western land-sea new channel Chongqing (Wansheng) inland waterless port low-carbon Industrial Park project has been promoted smoothly, and has entered the construction stage of the main structure of the plant. Among them, the entry project - Caster Aluminum integrated molding process lightweight new energy auto parts project (referred to as: Caster Aluminum project) has landed and started construction.

It is understood that the caster aluminum project covers an area of about 220 acres, divided into two phases of construction, after the completion of the project, will form an annual output of 1 million sets of integrated molding process lightweight new energy auto parts production capacity. At present, the foundation of the No. 3 plant of the project has been leveled and entered the main construction of the steel structure of the plant, and it is planned to build a 30,000 square meter plant, among which the foundation pile construction of the No. 1 office building and the No. 2 plant are under construction and will soon enter the construction stage of the main building.

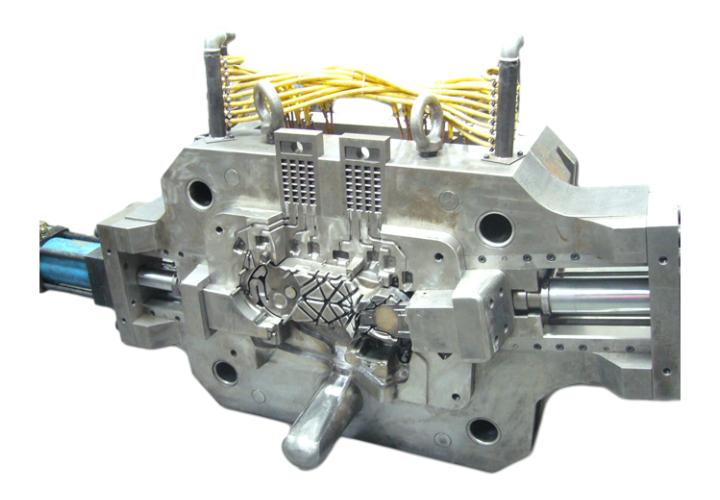

The Chongqing Castor Aluminum project is invested by Changzhou Castor Aluminum Precision Casting Technology Co., LTD. The project is implemented by Castor Aluminum (Chongqing) Technology Co., LTD., a wholly-owned subsidiary of Changzhou Castor Aluminum in Chongqing. Changzhou Castor Aluminum is engaged in the design, production and sales of aluminum parts for the automobile industry and rail transit industry, and its products involve many fields such as automobile, rail transit, aerospace equipment, military equipment, wind energy and so on

new energy vehicle parts

Previous Page

28

2025-10

Elevating Quality Standards: The Role of Aluminum Casting in Mechanical Processing

25

2025-10

22

2025-10

Efficiency Redefined: Advancements in Zinc Die Casting for Molding

19

2025-10

Understanding Die Casting Machines: An Essential Guide for Metalworking Professionals

16

2025-10

Unleashing the Potential of Aluminum Die Casting in Modern Manufacturing

13

2025-10

Understanding Aluminum Alloy Molds: A Key Component in Precision Manufacturing

GM Diecasting Technology Co.,Limited.

Add:Building 1-5, Chongke Road, Shipai Town, Dongguan City, Guangdong Province

Email:henry@gmdiecastingtech.com

Email:lily@gmdiecastingtech.com

Tel:+8613680864695